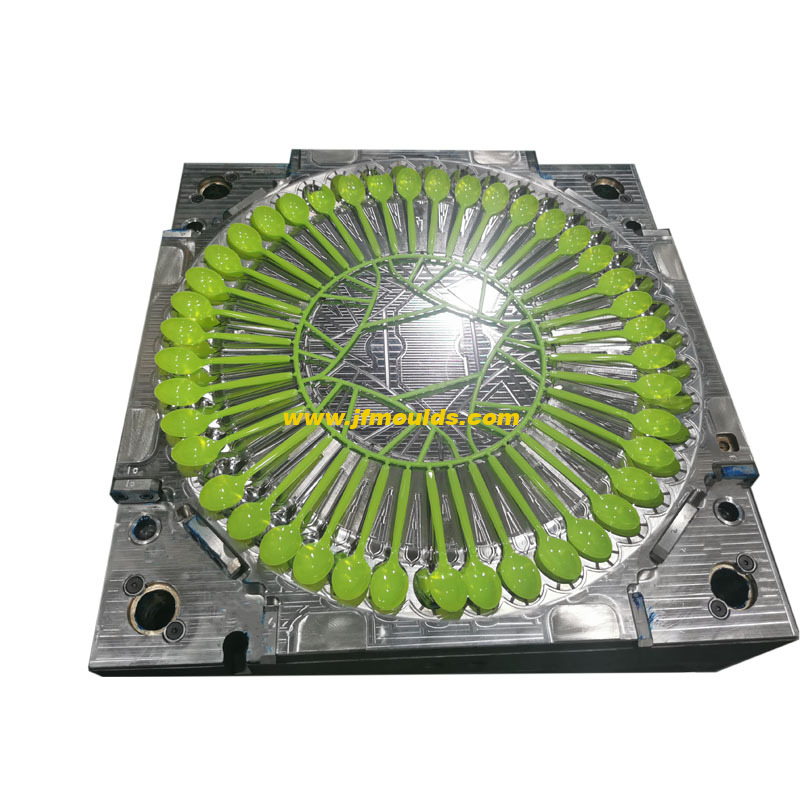

Acuan suntikan sudu plastik

Butiran

Pengeluar sudu plastik

Sebagai salah satu pengeluar acuan sudu plastik domestik yang paling kompetitif dan terkemuka, Jiefeng Mold telah memberi tumpuan kepada penyelidikan, pembangunan, dan pengeluaran acuan tersebut selama lebih dari sepuluh tahun. Dengan teknologi canggih, pengalaman yang luas, dan sistem kawalan kualiti yang ketat, kami sentiasa dapat menyediakan pelanggan global dengan acuan spoon plastik yang berkualiti tinggi, sangat tahan lama, dan berkualiti tinggi, membantu pengeluar keperluan harian mewujudkan produk dengan daya saing pasaran yang lebih kukuh.

Maklumat asas:

| Nama acuan | Acuan suntikan sudu plastik |

| Bahan acuan | P20,45# Steel, S136, H13.718h, dan lain -lain. |

| Pelari | Pelari panas |

| Jenama Runner Hot | Judo |

| Perisian reka bentuk | dan |

| Kehidupan acuan | 1.000.000 |

| Masa penghantaran | 35-60days |

| Bahan plastik | PP PC ABS PE PVC ABS+PC PS.ETC. |

| Tempoh jaminan | satu tahun |

| Acuan rongga | Rongga tunggal |

| Jenis Pintu | Pintu Pintu, Pintu Kelebihan, Pintu Sub, Pintu Filem, Pintu Injap, Pintu Terbuka, Makan |

| Rawatan permukaan acuan | EDM, tekstur, penggilap gloss tinggi |

| Sistem Kualiti | SGS |

| Asal | Dibuat di China |

| Pemasangan | tetap |

| Rongga | Single/Multi |

| Spesifikasi | Bergantung pada keperluan pelanggan |

| Sistem penyejukan acuan | penyejukan air atau penyejukan gangsa berilium. dll. |

| Acuan rawatan panas | Quencher, Nitridation, Tempering.etc. |

| Saiz pembungkusan (mm) | 500*500*450 |

| Berat pembungkusan berat | 650kg |

Kelebihan kami:

1. Kelebihan Teknologi dan Proses:

Mempunyai keupayaan reka bentuk acuan profesional (seperti mengoptimumkan struktur menggunakan perisian CAD/CAM/CAE), yang menjadi familiawith ciri-ciri pembentukan bahan-bahan yang berbeza (seperti PP, ABS, PC), yang mampu menyelesaikan masalah pembuatan acuan yang kompleks (seperti dinding nipis, pelbagai kaviti, dan corak Precise)

2. Keupayaan Pengoptimuman Kos:

Melalui pengeluaran berskala besar, integrasi rantaian bekalan (seperti perolehan pukal bahan mentah). dan mengoptimumkan kehidupan omold, kos setiap acuan dan kerugian dalam pengeluaran suntikan suntikan berikutnya dapat dikurangkan. Pada masa yang sama, perkhidmatan acuan "acuan + iniection" boleh disediakan untuk mengurangkan kos tambahan penyambungan sambungan pelbagai pautan.

3. Penyampaian dan kecekapan perkhidmatan

Dengan proses dan peralatan pengeluaran matang (seperti pusat pemesinan CNC dan mesin EDM EDM). Kitaran pembangunan boleh dipendekkan (biasanya dari reka bentuk ke acuan percubaan boleh dimampatkan hingga beberapa minggu). Pada masa yang sama, penyelenggaraan selepas jualan (seperti pembaikan dan penyelenggaraan acuan) dan perkhidmatan pengubahsuaian acuan cepat untuk mengurangkan masa pengeluaran pelanggan.

4. Keupayaan Kawalan Kualiti:

Mewujudkan piawaian pemeriksaan kualiti proses yang penuh (dari kemasukan bahan mentah, pemeriksaan proses pemprosesan kepada sampingan), dan beberapa pengeluar memperoleh 1S0 dan pensijilan sistem lain dapat memastikan operasi stabil jangka panjang dan mengurangkan kadar pemecatan produk yang disebabkan oleh kecacatan acuan

Acuan jiefengakan menyediakan analisis FOW pelanggan. dan gunakan perisian simulasi untuk mengesahkan butiran asas pendawaian, ubah bentuk, dan reka bentuk mati yang lain. Ciri -ciri ini akan menentukan kualiti yang tinggi die untuk memastikan tahap awal projek dan memastikan kejayaan di T1

Kami menyediakan pelbagai teknologi pemprosesan, sehingga lima perisian AxeSthe sesuai untuk semua pengaturcaraan 2D, 3D, dan lima paksi. Mesin ini dilengkapi dengan penukar alat automatik dan alat penentukuran laser.

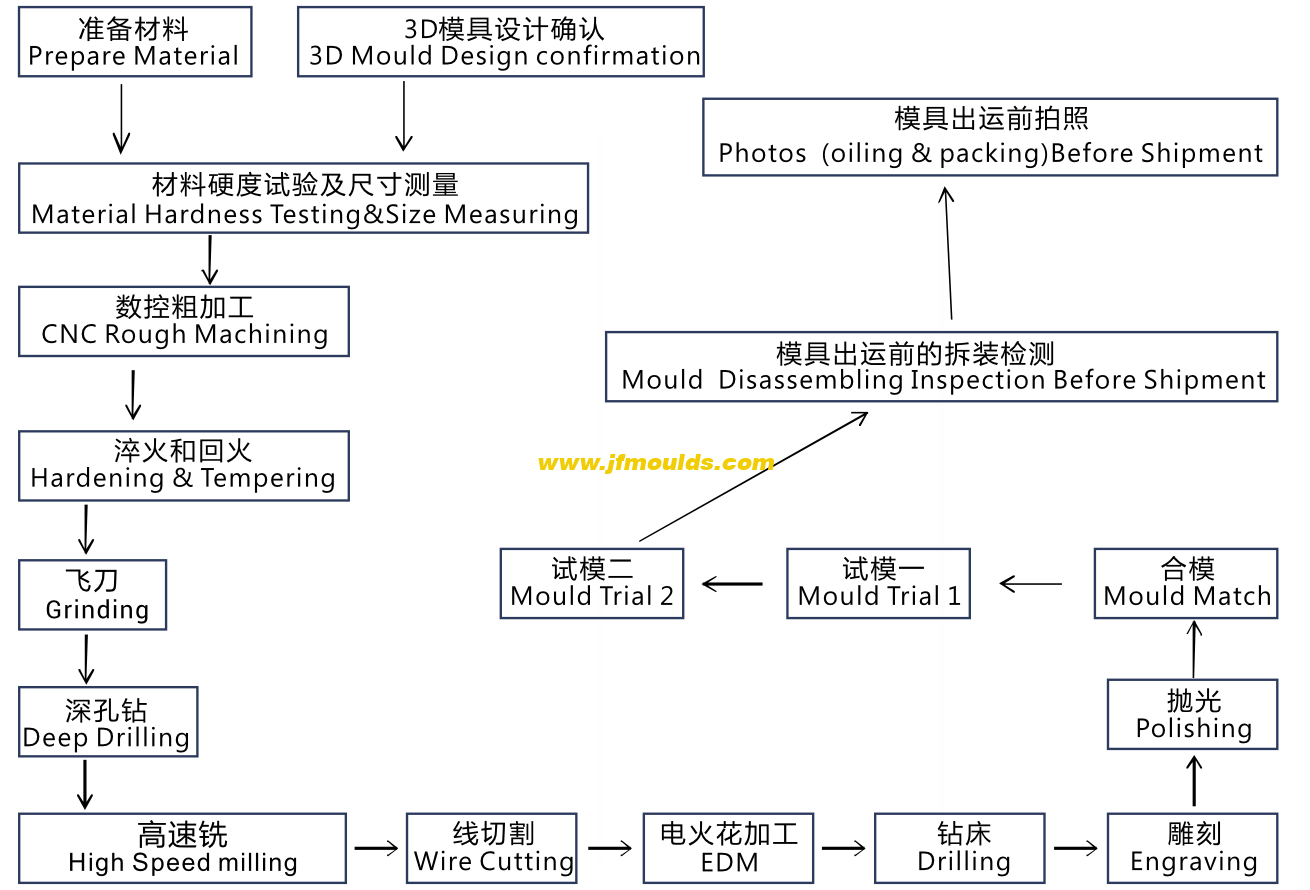

Mold flow chart:

Packaging and transportation:

Jiefang Mould, with its strict shipment inspection standards, systematic packaging protection system and rapid response after-sales mechanism, has built a full-chain safety guarantee closed loop from the factory to the customer's production line, ensuring that every set of moulds can be safely and reliably delivered and put into production.

1. Mold shipment: Multi-dimensional inspection builds a solid quality defense line

To ensure the quality of molds from the root, Jiefang has established a multi-stage and multi-level inspection mechanism. From the dimensional accuracy and structural strength of the molds to their surface finish and functional compatibility, all are subject to strict inspection by professional testing equipment and experienced quality inspection teams to ensure that each set of molds meets or even exceeds industry standards and customer requirements.

2. Professional Packaging: Standardized processes create a "safe fortress"

Jiefang adopts a standardized and refined full-process packaging technology to build an impregnable "safety fortress" for molds:

Cleaning and rust removal: Through professional cleaning equipment and rust removal processes, thoroughly remove oil stains, dust and rust on the surface of the mold to ensure its cleanliness.

Anti-rust protection: High-quality anti-rust materials are selected, and multiple anti-rust treatments such as spraying and soaking are adopted to coat the molds with a "protective armor", effectively resisting the risk of rusting during transportation and storage.

Sealed packaging: Use packaging materials with excellent sealing performance to tightly wrap the molds to prevent the invasion of external factors such as air and moisture.

Sturdy packaging: According to the size and weight of the mold, customize a sturdy packaging structure, such as high-strength wooden boxes, metal frames, etc., to ensure that the mold is not damaged by collision or compression during transportation.

3. Full-cycle technical support: One-stop service ensures smooth production

Warranty period: We offer industry-leading warranty period services. During the warranty period, if there are non-human-induced quality issues with the mold, free repair or replacement services can be enjoyed.

Standardized mold frame and maintenance for internal after-sales response: Establish a 7× 24-hour rapid response mechanism. After receiving the customer's after-sales request, the technical team will provide remote guidance or on-site service in the first instance. At the same time, standardized mold bases are provided to facilitate mold maintenance and upgrades, reducing maintenance costs.

Professional assembly guarantees post-warranty technical support: Equipped with a professional assembly team, we can provide on-site assembly and debugging services for molds to customers, ensuring rapid production of molds. Even after the warranty period, we still provide continuous support such as technical consultation and paid maintenance to help customers achieve long-term stable production.

From the rigorous layer upon layer of shipment inspection to the comprehensive packaging protection, and then to the always-on after-sales support, Jiefang Mould, with its professional, meticulous and full-cycle service system, ensures that customers have no worries at every stage of mold delivery and use, thereby fully guaranteeing their production efficiency and economic benefits, and becoming a solid backing for customers' mold procurement and production.