Kecacatan biasa produk acuan suntikan dan penyelesaiannya

Kecacatan biasa produk acuan suntikan dan penyelesaiannya

Diagnosis dan penyebab kecacatan produk biasa adalah seperti berikut.

(1) lekapan produk

Fenomena: lekukan atau gelembung, lubang keruntuhan, pengecutan, rongga pengecutan, gelembung vakum, dan lain -lain dalam produk adalah semua kecacatan produk.

Alasannya ialah disebabkan oleh tekanan yang lemah dan memberi makan, produk itu menyejukkan secara tidak sekata dan sebatian getah di rongga acuan tidak mencukupi, menyebabkan pengecutan plastik yang berlebihan. Ini mengakibatkan penyok, lubang keruntuhan, gelembung vakum, dan bayang -bayang berongga pada permukaan produk, memberikan penampilan yang tidak sekata.

(2) Produk siap tidak memuaskan

Fenomena: Bahagian plastik yang lemah, acuan yang tidak lengkap, dan permukaan gelembung yang tidak lengkap adalah semua kecacatan produk siap yang tidak lengkap.

Sebab -sebab utama adalah ketidakstabilan bahan yang lemah, pemakanan yang tidak mencukupi, aliran pengisian bahan cair yang lemah, inflasi yang berlebihan dan ekzos yang lemah, yang menyebabkan pengisian rongga acuan yang tidak lengkap, mengakibatkan bentuk plastik yang tidak lengkap dan tidak lengkap atau pengisian rongga individu atau pengisian acuan miskin apabila terdapat banyak rongga.

(3) FLASH PRODUK

Fenomena: Flash yang berlebihan dan tepi kasar kebanyakannya kecacatan burrs produk.

Alasannya ialah disebabkan oleh pengapit yang kurang acuan, halangan yang berlebihan atau jurang di pinggir acuan, kelemahan plastik yang terlalu baik, dan suntikan yang berlebihan dari sebatian getah, produk bahagian plastik mempunyai sayap nipis tambahan, tepi flaky, dan lain -lain di sepanjang tepi.

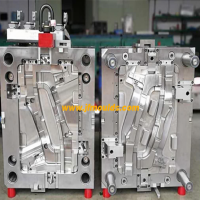

Kereta Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

(4) kimpalan produk yang lemah

Fenomena: Tanda kimpalan yang jelas dan garis gabungan permukaan adalah semua kecacatan kimpalan miskin dalam produk.

Alasannya ialah disebabkan oleh pencemaran bahan, penyejukan sebatian getah yang berlebihan, dan penggunaan agen pelepasan acuan yang berlebihan, kandungan kelembapan bahan cair dan campuran berkurangan, dan resin dan lampirannya tidak boleh dilarutkan. Sebab -sebab ini membawa kepada gabungan yang lemah semasa aliran bahan lebur dan campuran, menyebabkan lipit halus yang jelas atau garis gabungan yang lemah di sepanjang permukaan atau di dalam produk.

(5) retak dalam produk

Fenomena seperti menarik retak, retak atas, pecah dan retak shell kura -kura adalah semua kecacatan retak produk.

Sebab -sebab: Oleh kerana tekanan dalaman yang berlebihan terhadap produk, demolding yang lemah, penyejukan yang tidak sekata, nisbah pencampuran plastik yang tidak betul, prestasi yang lemah, dan reka bentuk acuan yang lemah atau penetapan parameter yang tidak wajar seperti tekanan pin lonjakan yang berlebihan, retak, retak halus, retak atau retak di bawah beban dan tindakan pelarut berlaku di permukaan produk.

(6) ubah bentuk produk

Fenomena seperti ubah bentuk, warping, pembengkakan permukaan, dan ketidakstabilan dimensi adalah semua kecacatan ubah bentuk produk.

Sebab akibat tekanan dalaman yang disebabkan oleh tekanan sisa, tekanan ricih, ketebalan dinding yang tidak sekata dari produk dan pengecutan yang tidak sekata semasa pengacuan suntikan, bersama -sama dengan demolding yang lemah, penyejukan yang tidak mencukupi, kekuatan produk yang tidak mencukupi, ubah bentuk dan sebab -sebab lain, dan ketepatan, operasi mesin pencetakan suntikan yang tidak stabil, dan keadaan teknikal proses yang tidak stabil, perubahan dimensi produk tidak stabil.

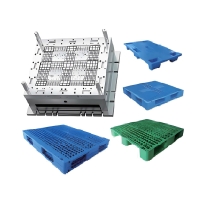

Komoditi Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

(7) corak perak pada produk

Fenomena: Corak benang perak, corak awan permukaan, corak perak permukaan, dan lain -lain adalah semua kecacatan corak perak pada produk.

Sebabnya adalah disebabkan oleh kelembapan yang berlebihan, pengudaraan yang berlebihan atau terlalu banyak bahan yang tidak menentu dalam bahan mentah plastik, bahan cair tertakluk kepada ricih yang berlebihan, permukaan acuan cair yang kurang dimetera produk.

(8) perubahan warna produk

Fenomena: Perbezaan warna, pewarnaan yang tidak sekata, dan perubahan warna produk adalah semua kecacatan perubahan warna produk.

Reason Due to poor distribution of pigments or fillers, material contamination and degradation, excessive volatile substances in materials, and decomposition of colorants and additives, plastics or pigments may change color, resulting in color differences on the surface of the products. Products with uneven color are often related to the poor thermal stability of plastics and raw materials. Uneven color in the welded part is often related to the deterioration and degradation of pigments (uneven color refers to the phenomenon where the color of the product is either darker or lighter and inconsistent with the standard color after comparison).

(9) Product corrugations

Phenomena: Surface ripples, flow patterns, plastic surface ripples, etc. are all ripple defects of the products.

The reason is that the molten material does not flow smoothly along the mold surface to fill the cavity, but rather flows in a semi-cured and fluctuating state along the mold cavity surface. There is a retention phenomenon of the molten material, causing ripples.

(10) The product is rough

Phenomena: Dull surface, rough surface, mold spots, streaks, scratches, mold marks, handprints, etc. are all manifestations of rough or unsmooth products.

The main reasons are insufficient surface finish of the mold, poor adhesion between the molten material and the mold surface, other impurities adhering to the mold or surface marks after mold maintenance and repair, improper operation, lack of cleanliness, and improper setting of parameters such as material temperature and mold temperature, which result in the product surface being not bright, having marks, not smooth, scratches and scars, mold marks, and the surface being milky white or whitish.

(11) Bubbles in the product

Phenomenon: Defects such as internal vacuum bubbles in the product or bubbles in expanded products.

The reason is that due to excessive inflation or poor venting in the molten material, the remaining monomers, gases and moisture inside the product form small or string cavities or vacuum bubbles.

(12) The product sticks to the mold

Phenomena: Poor demolding, plastic part sticking to the mold and other defects.

The reason is that due to material contamination or non-drying, poor demolding performance of the mold, overly strong filling effect, etc., the products are difficult to demold or deform or crack after demolding, or the residual direction of the products does not meet the design requirements.

(13) The products delaminate and peel off

Phenomena: Defects such as delamination and peeling of mica flakes, and layered plastic at the gate.

The reason is that due to improper raw material mixing ratio, improper material temperature or mold temperature, uneven plasticization, and excessive shear force when the molten material flows along the mold surface, the material peels off in thin layers, resulting in a decline in the physical properties of the product.

(14) Gate sticking to the mold

Phenomena: Gate or sprue blockage, broken glue, broken pins, runner sticking to the mold, and sprue sticking to the mold are all gate sticking defects. In mild cases, the mold sticks; in severe cases, it gets clogged.

The reason is that due to insufficient design of the gate opening and the slope of the gate, the limited force acting inside the gate sleeve, or insufficient cooling, the gate adheres to the gate sleeve or blocks the sprue, etc.

(15) The product is cloudy

Phenomenon: Poor transparency, turbidity defect at the gate of the product.

The reasons are as follows: Due to material contamination and poor drying, poor contact between the molten material and the mold surface, fine depressions on the product surface causing random light scattering or plastic decomposition, and the presence of impurities and waste materials, the mold surface is not bright, and the exhaust is not good, which can cause the transparent plastic to be poorly transparent or uneven.

(16) Spots on the product

Phenomenon: Black spots, black lines, yellow spots, yellow lines, black stripes, brown stripes, etc. on the product are all spot defects of the product.

Reason: Due to the decomposition of plastic or the decomposition and combustion of flammable volatile substances, air, etc. in the material under high temperature and high pressure, the burned resin is injected into the mold cavity along with the molten material, presenting various spots on the surface of the product, such as black spots, yellow spots, black stripes, brown stripes, etc., or along the surface of the product, it shows a grayish burn.

(17) Stiff lumps of the product

Phenomenon: Defects such as cold lumps or hard lumps in the product.

The reason is that due to the addition of cold materials or poorly plasticized rubber compounds, these unplasticized and insufficiently plasticized materials cause the plastic products to be undercooked.

(18) Glue leakage

Phenomena: Defects such as material overflow and glue dripping from the nozzle.

The reasons are: The temperature setting of the barrel and the nozzle is improper, the contact between the nozzle and the main gate die is poor, the clamping force is uneven or unstable, the fluidity of the plastic is too good, and the temperature of the nozzle is too high, resulting in the phenomenon of glue leakage and material overflow.

Defects in injection molding products are the root cause of substandard product quality, and these defects are also related to the technical proficiency of injection molding operators and maintenance workers. To ensure product quality, injection molding operators are required to have rich practical experience in injection molding machines and process technologies. One should be familiar with and understand the performance of the injection machine being used, and have a comprehensive grasp and application of it. It is necessary to have a comprehensive grasp of injection molding process technology and master the entire process setting and calibration from plastic raw materials to product packaging.

During the injection molding operation process, common product defects also have certain trends. The common practice is to accurately identify and diagnose product defects, comprehensively analyze the possible causes, and combine practical work experience to explore a set of rules. Through the setting of plastic raw materials, various temperature parameters, pressure parameters, speed parameters, stroke parameters, and time parameters, In light of specific circumstances such as molds, nozzles, melt tubes, screws, as well as lubricants and mold release agents, reasonable parameter presetting and modification should be carried out. The process technical parameters should be adjusted and corrected in combination with the actual situation. Through calibration and trial operation, product defects can be prevented and product quality can be guaranteed to be qualified.

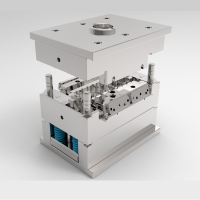

Pemprosesan equipment_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

Maklumat Berkaitan

Meneroka kitaran hayat penuh acuan suntikan dan pemikiran mengenai penemuan industri

2025-07-15

Meneroka kitaran hayat penuh acuan suntikan dan pemikiran mengenai...

Proses pemprosesan reka bentuk pembuatan acuan

2025-06-19

Aliran proses 1. Pembuatan acuan adalah seperti berikut: lukisan kajian-bahan...

Acuan suntikan yang biasa digunakan enam jenis bahan acuan

2025-06-19

Pilihan keluli bukan sahaja memberi kesan kepada hayat perkhidmatan acuan, tetapi juga...

Panduan komprehensif untuk acuan suntikan: dari asas ke aplikasi

2025-07-11

Panduan komprehensif untuk acuan suntikan: dari asas ke aplikasi dalam...

Ciri-ciri prestasi dan kriteria pemilihan acuan suntikan

2025-06-30

Ciri-ciri prestasi dan kriteria pemilihan acuan suntikan...

Dari pembangunan adat kepada bekalan global, membuka kunci daya penggerak teras pembuatan moden

2025-07-19

Dari pembangunan adat kepada bekalan global, buka kunci daya penggerak teras...