Punca dan penyelesaian jalur perak, perubahan warna, riak permukaan dan kekasaran dalam produk acuan suntikan

Punca dan penyelesaian jalur perak, perubahan warna, riak permukaan dan kekasaran disuntikan dibentukproduk

Kecacatan produk | Sebab yang mungkin | Penyelesaian | |

| Corak perak pada produk | 1. Pelet plastik plastik atau pelet plastik yang tidak sekata, pencemaran atau perkadaran yang tidak wajar. 2. Plastik mengandungi kelembapan yang tinggi dan mempunyai bahan yang tidak menentu yang rendah bercampur. 3. Sebilangan kecil udara bercampur ke dalam plastik. 4. Pelekat cair tidak mengalir secara berterusan dalam rongga acuan. 5. Terdapat kelembapan, minyak pelincir, atau penggunaan ejen pelepasan acuan yang berlebihan atau tidak wajar pada permukaan acuan. 6. Apabila acuan mempunyai ekzos yang buruk dan bahan cair berdinding nipis mengalir ke dalam berdinding tebal, ia mengembang, dan bahan-bahan yang tidak menentu menguap dan mencairkan apabila dihubungi dengan permukaan acuan untuk membentuk filamen perak. 7. 8. Masa suntikan gam ditetapkan terlalu pendek. 9. Masa pemegangan tekanan ditetapkan terlalu pendek 10. Suhu plastik terlalu tinggi atau tekanan belakang terlalu tinggi. 11. Terdapat halangan atau burrs yang mempengaruhi laras atau muncung. | 1. Mengawal formula perkadaran plastik. Bahan bercampur harus seragam dalam ketebalan untuk memastikan plasticisasi. 2. Keringkan plastik sebelum pengeluaran untuk mengelakkan pencemaran. 3. Kurangkan suhu di hujung belakang silinder cair atau tingkatkan suhu di bahagian depan silinder cair. 4. Apabila menyesuaikan pintu, pastikan mereka simetri. Tentukan kedudukan pintu atau simpan seragam suhu acuan. 5. Lap kering kelembapan atau noda minyak di permukaan acuan dan gunakan ejen pelepasan acuan dengan munasabah. 6. Meningkatkan reka bentuk acuan, dengan ketat mengawal perkadaran dan formula bahan mentah plastik sebanyak mungkin, dan mengurangkan pencemaran bahan mentah. 7. Meningkatkan suhu acuan, menaikkan tekanan suntikan dan kelajuan, dan lanjutkan masa penyejukan dan masa kitaran pencetakan suntikan. 9. Meningkatkan nilai penetapan parameter untuk masa suntikan dan nilai penetapan parameter untuk masa tekanan pegangan. 10. Bermula dari muncung, kurangkan suhu silinder cair atau menurunkan kelajuan skru untuk mengurangkan tekanan belakang pada skru. 11. Check the barrel and nozzle. The gating system is too rough and should be improved and enhanced | |

| The product has changed color. | 1.Impurities are mixed into plastic and pigments. 2. Plastic and pigment pollution or degradation, decomposition. 3. The quality of the pigment is poor or it is not stirred evenly during use. 4. The temperature of the barrel and the nozzle is too high, causing the rubber compound to burn and change color. 5. The injection pressure and speed were set too high, causing the additives and colorants to decompose. 6. There is moisture, oil stains on the surface of the mold, or mold release agents have been used .. 7. The distribution of fiber fillers is uneven. When the product comes into contact with the solvent, the resin dissolves, leaving the fibers exposed. 8. Obstacles in the glue melt cylinder promote the degradation of materials. | 1.When mixing materials, avoid mixing in any impurities. 2. The raw materials should be dry and the equipment clean. When changing materials, they should be thoroughly cleaned to avoid leaving any excess materials. 3. Ensure the quality of the pigments used. When stirring, the pigments should be evenly adhered to the surface of the material particles. 4. Lower the temperature of the glue cylinder and the nozzle to remove the charred glue. 5. Reduce the injection pressure and speed parameter values to prevent the decomposition of additives. 6. Dry the moisture and oil stains on the surface of the mold and use the mold release agent reasonably. 7. Set the process parameters of fiber fillers reasonably and use solvents properly to ensure good plasticization and eliminate fiber exposure. 8. Pay attention to eliminating obstacles, especially when changing materials, strictly follow the step-by-step procedures or use the transitional material change method. | |

| Corrugations on the surface of the product | 1.The small gate causes the rubber compound to spray inside the mold cavity. 2. The flow channel is tortuous, narrow, with poor smoothness and insufficient supply of rubber compound. 3. The cut surfaces of the products are uneven in thickness, large in area and complex in shape. 4. Improper mold cooling system or low mold temperature. 5. Low material temperature, low mold temperature or low nozzle temperature. 6. The injection pressure and speed Settings are too low. | 1.Modify the gate size or reduce the injection pressure. 2. Modify the flow channel and enhance its smoothness to ensure sufficient supply of the rubber compound. 3. Design the product to ensure uniform thickness of the cut surface, or remove the protruding discs and raised lines on the product. 4. Adjust the cooling system or add molds. 5. Increase the temperature of the glue melt cylinder and the nozzle. 6. Increase the set values of the injection pressure and speed parameters. | |

| The product is rough | 1.The mold cavity is rough and has poor smoothness. 2. Plastic meat contains excessive moisture or volatile substances, or plastic pigments have decomposed and deteriorated. 3. Insufficient feeding, poor curing or poor fluidity of the plastic. 4. There is moisture and oil stains on the mold wall. 5. Excessive use of mold release agent or improper selection. 6. The molten material in the mold cavity does not fully contact the cavity wall. 7. Slow injection speed and low pressure. 8. The draft Angle is small, resulting in poor draft or low surface hardness of the product, which is prone to scratches and wear. 9. Uneven particle size or the mixture of immiscible materials can cause uneven color, silver streaks, etc. | 1.Polish the mold cavity again. 2. Dry plastic raw materials, use recycled materials reasonably, and prevent impurities from being mixed in. 3. Check the condition of the discharge port and the plasticization of the plastic material, and then adjust the parameters. 4. Clean and repair water leakage cracks or prevent water vapor from condensing on the wall surface, and wipe off oil stains. 5. Select a small amount of mold release agent correctly to clean the mold. 6. It can be improved by increasing the injection pressure, raising the mold temperature and increasing the feed. 7. Increase the injection pressure and speed Settings, raise the melt temperature, and increase the back pressure. 8. Modify the mold slope, select the ejector pin parameters reasonably, and operate carefully. 9. When mixing materials, pay attention to the uniform size of the material particles to prevent other materials from entering by mistake. |

Kereta Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

Komoditi Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

Maklumat Berkaitan

Rawatan permukaan acuan

2025-07-26

Rawatan permukaan acuan1. Rawatan permukaan biasa memproses tujuan o ...

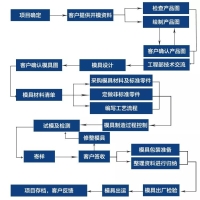

Koleksi proses pembuatan acuan, piawaian, proses dan kes.

2025-06-19

Carta aliran proses adalah seperti berikut: Semua jenis alat dan produk yang digunakan dalam OU ...

Acuan suntikan yang biasa digunakan enam jenis bahan acuan

2025-06-19

Pilihan keluli bukan sahaja memberi kesan kepada hayat perkhidmatan acuan, tetapi juga...

Bahagian acuan standard

2025-07-24

Bahagian standard acuan acuan acuan rangka acuan standard acuan standard ...

Kepelbagaian perusahaan acuan suntikan

2025-06-28

Kepelbagaian acuan suntikan enterprises1. Acuan automotif: memandu...

Punca dan penyelesaian jalur perak, perubahan warna, riak permukaan dan kekasaran dalam produk acuan suntikan

2025-07-30

Punca dan penyelesaian jalur perak, perubahan warna, riak permukaan dan ...