Penyelesaian kepada masalah seperti ketelusan yang lemah, dimensi yang tidak stabil, bintik -bintik, dan garis hitam dalam produk acuan suntikan

Penyelesaian kepada masalah seperti ketelusan yang lemah, dimensi yang tidak stabil, bintik, dan garis hitam diProduk acuan suntikan

Kecacatan produk | Sebab yang mungkin | Penyelesaian | |

| Ketelusan produk yang lemah | 1. Plastik mengandungi kelembapan atau kekotoran yang dicampur. 2. Saiz pintu terlalu kecil, bentuknya tidak baik atau kedudukannya tidak sesuai. 3. Permukaan acuan tidak licin, dengan kelembapan atau noda minyak. 4. Suhu plastik adalah rendah, atau suhu acuan adalah rendah. 5. Suhu bahan yang tinggi atau kesan ricih yang signifikan dari sistem gating membawa kepada penguraian plastik. 6. Hubungan yang lemah antara bahan cair dan permukaan acuan atau ekzos miskin dari acuan. 7. Penggunaan pelincir yang tidak betul atau dos yang berlebihan. 8. Plastik yang lemah plastik, penyejukan bahan kristal yang lemah atau tidak sekata atau ketebalan dinding yang tidak sekata produk. 9. Kelajuan suntikan terlalu cepat dan tekanan suntikan terlalu rendah. | 1. Plastik harus dikeringkan sebelum pengacuan dan kekotoran suntikan harus dicegah daripada bercampur. 2. Ubah saiz saiz, bentuk atau kedudukan pintu acuan untuk menjadikannya munasabah. 3. Keringkan kelembapan atau noda minyak dan menggilap permukaan. 4. Meningkatkan suhu silinder cair plastik atau suhu acuan. 5. Kurangkan suhu bahan untuk mencegah kemerosotan plastik atau penguraian. 6. Munasabah menyesuaikan tekanan suntikan dan parameter kelajuan, dan periksa keadaan ekzos saluran ekzos. 7. Gunakan jumlah pelincir yang sesuai. 8. Munasabah menyesuaikan parameter teknologi proses untuk mengelakkan penyejukan bahan kristal yang miskin atau tidak sekata. 9. Laraskan kelajuan suntikan dan tekanan untuk menjadikannya sesuai. | |

| Saiz produk tidak stabil | 1. Sistem elektrik dan hidraulik mesin tidak stabil. 2. Keadaan teknikal proses pencetakan suntikan tidak stabil. 3. The technical conditions for injection molding process were improperly set. 4. Insufficient mold strength, bent or worn guide pins. 5. Unstable mold clamping, poor precision, unstable movement of moving parts, and inaccurate positioning. 6. Uneven plastic feeding or uneven particle size, poor plastic plasticization or wear of the machine's melt cylinder and screw. 7. The cooling time of the product is set too short, and the cooling is uneven after demolding. 8. Poor rigidity of the products, uneven wall thickness and unstable post-treatment conditions. 9. Improper plastic mixing ratio, unstable plastic shrinkage or unstable crystallinity of crystalline materials. | 1.Inspect and calibrate the electrical and hydraulic control system of the machine to ensure stable and normal control. 2. Check whether the process technical parameters are stable, whether the feeding system is normal, whether the temperature control system is normal, whether the screw speed is normal, whether the back pressure is stable, and whether the hydraulic systems of each action in injection molding are stable and normal, etc. 3. Check whether the injection pressure is normal, whether the injection and holding time Settings are normal, whether the production cycle is stable, and whether the pressure and speed parameter Settings for each action in injection molding are appropriate. 4. Check whether the guide pins are worn or bent and deformed. 5. Check the precision of the mold and the movement and positioning of the parts, eliminate adverse factors, and ensure that all movements are stable and normal. 6. Check the machine performance. If the gap between the glue cylinder and the screw is too large or the wear is severe, replace or repair it. 7. Extend the cooling time and check the operating condition of the cooling system. 8. Inspect the molds or adjust the process parameters to enhance the stability of post-treatment conditions. 9. Reasonably combine the proportion of recycled materials or waste materials. For materials with unstable crystallinity, make up for it through processes, raw materials, etc. | |

| The product shows spots, black lines, etc | 1.The inner wall of the glue melt cylinder was charred, and the glue blocks fell off, forming small black dots. 2. Air pollution or air inside the mold cavity leads to coking and the formation of black spots. 3. Produce black stripes a. The barrel, screw, or raw materials are not clean. b. Local overheating of the rubber compound in the barrel. c. Cold rubber particles rub against each other and burn when rubbing against the wall of the molten rubber cylinder. d. There is a deviation in the center of the screw, causing it to rub against the wall of the melt cylinder and burn the plastic. e. The nozzle temperature is too high, burning the rubber compound. f. The rubber compound stays in the melt cylinder for too long at high temperatures. 4. Produce brown stripes or yellow lines, etc a. The entire or part of the glue cylinder is overheated. b. The rubber compound adheres to the wall of the glue melt cylinder or the nozzle, resulting in charring. c. The rubber compound stays in the melt cylinder for too long. d. There are dead corners inside the barrel. | 1.Remove the burnt material on the inner wall of the melt glue cylinder: Replace the material in the cylinder with a harder plastic to clean the inner wall of the cylinder. Avoid prolonged use of the rubber compound Occasionally exposed to high temperatures. 2. The plastic should be well sealed and covered with a lid on the hopper. The exhaust duct of the tool and die needs to be modified properly. Modify the design of the die or product or the position of the gate; Increase or decrease the temperature of the melt cylinder and the die to change the flow pattern of the rubber compound in the die. The setting for reducing the injection pressure or speed. 3. Handle them respectively in the following ways. A. Clean the barrel and screw, using a clean and impurity-free raw rice hopper. b. Lower or heat the melt cylinder evenly to ensure uniform temperature. c. Plastics with external lubricants adde d; Lubricant should be added to the recycled materials. Increase the temperature at the rear end of the glue melt cylinder. d. Correct the gap between the screw and the melt glue cylinder to ensure that air can be smoothly discharged from the melt glue cylinder; Avoid using fine powder plastic and avoid the screw and melt glue Frictional heat is generated between the wall surfaces. Fine plastic materials should be granulated before use. e. Reduce the temperature of the nozzle or control the range of temperature variation. f. Try to shorten the molding cycle time as much as possible; Reduce the screw speed, increase the back pressure or perform injection molding on a small-capacity injection molding machine; Try to make plastic as much as possible The material does not remain in the glue melt cylinder. 4. Handle them respectively in the following ways. a. Lower the temperature setting of the glue melt cylinder; Reduce the rotational speed of the screw; Reduce the set value of the screw back pressure. b. Clean the inner wall of the melt glue cylinder, the inner diameter of the nozzle, etc. at the same time and wipe them clean. c. Modify process parameters to shorten the injection molding cycle. d. Replace the screw. |

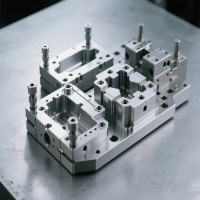

Motosikal Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

Maklumat Berkaitan

Punca dan penyelesaian penyok pada produk acuan suntikan, produk siap yang tidak lengkap, dan memancarkan produk

2025-07-29

Punca dan penyelesaian penyok pada produk suntikan yang dibentuk, Finis tidak lengkap ...

Acuan suntikan: "pencipta tidak kelihatan" di bengkel

2025-07-09

Acuan suntikan: "pencipta tidak kelihatan" di workshopI. Kesan pertama th...

Meneroka acuan suntikan: analisis komprehensif dari reka bentuk ke aplikasi

2025-07-08

Meneroka acuan suntikan: analisis komprehensif dari reka bentuk ke...

Kecacatan biasa produk acuan suntikan dan penyelesaiannya

2025-07-29

Kecacatan biasa produk acuan suntikan dan penyelesaian mereka diagnosis ...

Penyelesaian kepada masalah seperti ketelusan yang lemah, dimensi yang tidak stabil, bintik -bintik, dan garis hitam dalam produk acuan suntikan

2025-07-31

Penyelesaian kepada masalah seperti ketelusan yang lemah, dimensi yang tidak stabil, bintik -bintik, dan ...

Reka bentuk acuan berganda

2025-07-25

Proses Pelabelan Reka Bentuk Lipat Mold ProcessThin Plastik Plastik ...