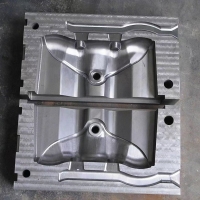

Lukisan acuan dan pengunduran pintu gerbang

Lukisan acuan dan pengunduran pintu gerbang

Lukisan acuan

Fenomena: Kedua -dua produk adalah produk bertekstur dan terdapat fenomena acuan menarik.

Analisis: Kelajuan perlahan akan menyebabkan produk menyejukkan terlalu cepat. Kedudukan bertukar terlalu lambat.

Ciri -ciri mesin pencetakan suntikan

Gred: Demag (Ningbo), Pasukan Pengapit: 120T, Kapasiti Plastik: 130g.

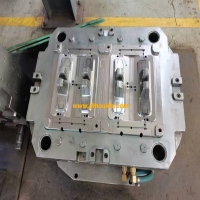

(2) Ciri -ciri acuan

Nombor ecect acuan: 1 × 2, kaedah suntikan gam: pintu masuk, kaedah lonjakan: lonjakan plat push, suhu acuan: 90 ° C (mesin suhu malar).

(3) Bukti Fizikal Produk

Bahan: PC+ABC HP5004-100, Warna: Hitam, berat produk (sekeping tunggal): 3.2g, berat muncung: 13g.

(4) analisis penyebab kecacatan

1. Saluran utama acuan panjang dan nipis. Kaedah masuk gam adalah masuk gam tenggelam. Bahan cair mengalir berhampiran salur masuk gam. Oleh kerana kelajuan perlahan, tekanan tempatan produk terlalu besar, mengakibatkan fenomena menarik acuan.

2. Keterbatasan peralatan itu sendiri telah menyebabkan ketidakupayaan untuk memperbaiki keadaan melalui pelarasan mesin.

(5) Penangguhan

Produk yang disahpepijat selepas menggantikan mesin Demag 100T layak, dan kelajuan suntikan mesin dapat mencapai 220mm/s.

Jadual proses pencetakan suntikan

Mesin Pencetakan Suntikan: Haiti 1201T, Jenis B Skru, Jumlah Suntikan 131g | Nama Produk: Bingkai Bateri M169 | ||||

Bahan mentah: ABS+PC HP5004 | Warna: Hitam | Suhu pengeringan: 100 ° C. | Kaedah pengeringan: pengering dehumidifikasi | Masa pengeringan: 4 jam | Penggunaan Bahan Kitar Semula: 0 |

| Berat produk siap: 3.2g × 2 = 6.4g | Berat Nozzle: 13g | Output acuan: 1 × 2 | Kaedah Suntikan Pintu: Pintu Pintu | ||

| Suhu barel | Suhu acuan | Gunakan mesin | "Tetapan | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 110°C | 102°C |

| 320°C | 315°C | 315°C | 300°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 110°C | 101°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 |

| ||

| / | 3 | Holding pressure time | 12 | 12 |  Injection pressure position Injection pressure position | ||||

Residual amount of injection glue | / | 10 | / | 55 | 3 |  Injection velocity Injection velocity | |||

| 7.8 | / | / | / | 12 | 23.5 |  Velocity of fire position Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Kereta Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

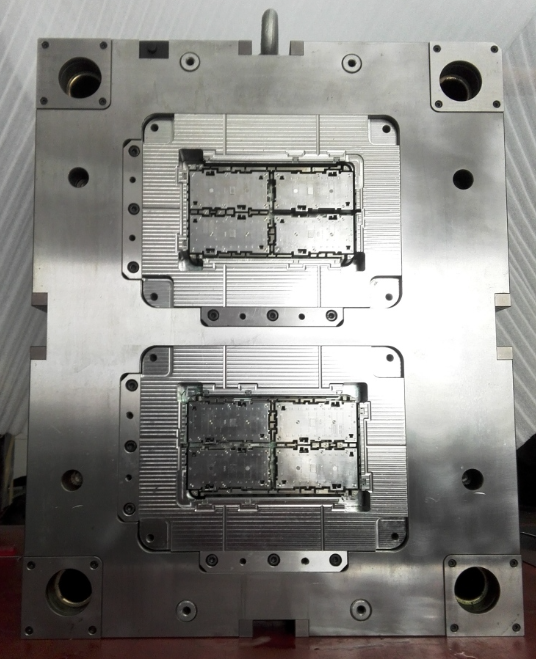

Mold ink flushing

Phenomenon: Ink surges at the gate of the S10 face frame.

Reason: During IML injection molding, the gate of the sheet material often appears transparent.

Analysis: High speed will cause material melting, intensify shearing and generate high temperatures. The ink has poor heat resistance.

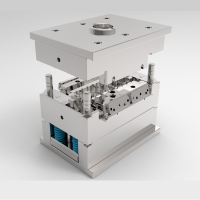

Ciri -ciri mesin pencetakan suntikan

Grade: DEMAG (Ningbo), clamping force: 50T, plasticizing capacity: 42g.

(2) Ciri -ciri acuan

Mold ejection number: 1×2, glue injection method: point gate, ejection method: push plate ejection, mold temperature: 70°C (constant temperature machine).

(3) Ciri -ciri produk

Material: ABS PA758, Color: Transparent, Product weight (single piece) : 1.5g, sprue weight: 13g.

(4) analisis penyebab kecacatan

1.The main channel of the mold is quite large, and the glue inlet method is submersible glue inlet. When the molten material flows near the glue inlet, due to the excessive speed, it causes high shear, resulting in a rapid and instant temperature rise of the molten material.

2. The ink is not resistant to high temperatures, resulting in ink flushing.

(5) Penangguhan

1.Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the area near the glue inlet at a slow speed and a very small position. In the third section, quickly fill 90% of the mold cavity to prevent the high-temperature molten rubber from cooling. In the fourth section, slowly fill the mold cavity. Finally, switch to the pressure-holding switching position.

Jadual proses pencetakan suntikan

Injection molding machine: DEMAG50T, Type B screw, injection capacity 42g | Nama Produk: Cermin telus | ||||

Raw material: ABS PA758 | Color: Transparent | Drying temperature: 70°C | Kaedah pengeringan: pengering dehumidifikasi | Drying time: 2 hours | Penggunaan Bahan Kitar Semula: 0 |

| Finished product weight: 1.5g×8=12g | Berat Nozzle: 13g | Mold output: 1×8 | Kaedah Suntikan Pintu: Pintu Pintu | ||

Suhu barel | Suhu acuan | Gunakan mesin | "Tetapan | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 70°C | 72°C |

| 260°C | 255°C | 250°C | 210°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 70°C | 71°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 |  Injection pressure Injection pressure | ||

| / | 3 | Holding pressure time | 12 | 12 |  Injection pressure position Injection pressure position | ||||

Residual amount of injection glue | / | 10 | / | 55 | 3 |  Injection velocity Injection velocity | |||

| 7.8 | / | / | / | 12 | 23.5 |  Velocity of fire position Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Komoditi Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

Maklumat Berkaitan

Punca dan penyelesaian penyok pada produk acuan suntikan, produk siap yang tidak lengkap, dan memancarkan produk

2025-07-29

Punca dan penyelesaian penyok pada produk suntikan yang dibentuk, Finis tidak lengkap ...

Percetakan baking permukaan dan cahaya dan bayangan acuan

2025-08-04

Percetakan baking permukaan dan cahaya dan bayang -bayang bakar cetakan dan p ...

Tentukan paradigma baru untuk industri acuan suntikan melalui penemuan teknologi dan pembinaan semula ekologi

2025-07-04

Menentukan paradigma baru untuk industri acuan suntikan melalui...

Acuan suntikan: asas pembuatan ketepatan dan trend baru dalam pembangunan industri

2025-07-08

Acuan suntikan: asas pembuatan ketepatan dan trend baru dalam...

Ciri-ciri prestasi dan kriteria pemilihan acuan suntikan

2025-06-30

Ciri-ciri prestasi dan kriteria pemilihan acuan suntikan...

Meneroka acuan suntikan: analisis komprehensif dari reka bentuk ke aplikasi

2025-07-08

Meneroka acuan suntikan: analisis komprehensif dari reka bentuk ke...

Injection pressure

Injection pressure