Kedudukan masuk gam acuan diseret dan hangus

Kedudukan masuk gam acuan diseret dan hangus

Salur masuk gam acuan tercalar

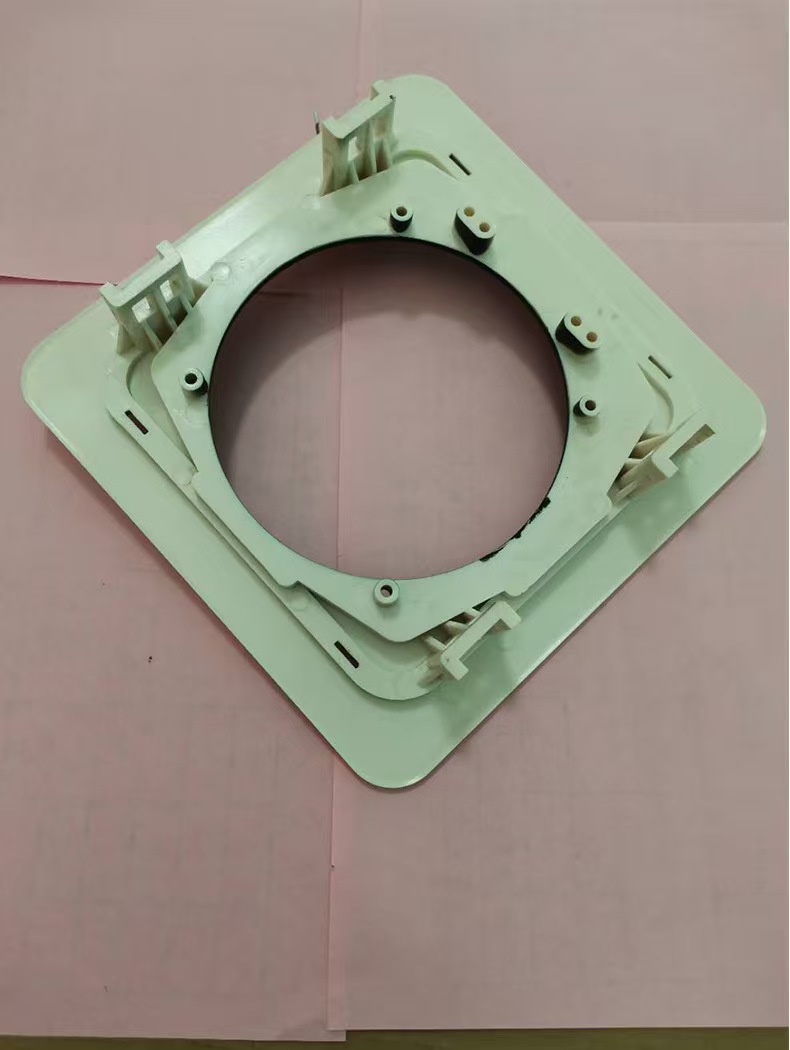

Fenomena: Tanda seret ditemui di kedudukan masuk gam selepas produk itu diturunkan.

Analisis: 1. Juruteknik percaya bahawa acuan itu tidak lancar dan meminta agar acuan dibaiki dan disewa untuk menyelamatkan acuan.

2 Jika tekanan suntikan terlalu rendah, produk akan mengecut.

(1) Ciri -ciri mesin pengacuan suntikan

Gred: Haiti, Pasukan Pengapit: 120T, Kapasiti Plastik: 150g.

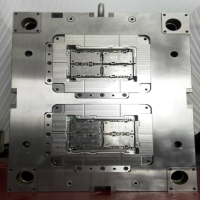

(2) Ciri -ciri acuan

Nombor Letupan Acuan: 1 × 2, Kaedah Suntikan Gam: Tenggelam, Kaedah Letakkan: Letakkan oleh Blok Atas, Suhu Acuan: Acuan Depan 110 ° C, acuan belakang 95 ° C (mesin suhu malar)

(3) Ciri -ciri produk

Bahan: PC K3037087, Warna: Kelabu telus, berat produk (sekeping tunggal): 10.16g, berat muncung: 5.8g

(4) analisis penyebab kecacatan

1. Produk ini tidak cukup disejukkan sebelum diturunkan.

2. Saluran getah untuk menyelam terlalu besar.

3. Kelajuan pembukaan acuan untuk papan A dan B tidak ditetapkan dengan betul.

(5) Penangguhan

1. Kurangkan saiz masuk gam sekali lagi dan gunakan suntikan pelbagai peringkat dan penukaran kedudukan.

2. Di bahagian pertama, isi saluran aliran ke salur masuk gam pada kelajuan yang agak cepat dan cari kedudukan pensuisan yang sepadan. Kemudian, di bahagian kedua, isi kawasan berhampiran salur masuk gam pada kelajuan perlahan dan kedudukan yang sangat kecil. Bahagian ketiga harus diisi dengan cepat hingga 90% rongga acuan untuk mencegah getah cair suhu tinggi dari penyejukan dan membentuk corak bergelombang. Di bahagian keempat, isi rongga acuan perlahan -lahan untuk mengusir udara di dalam rongga, mengelakkan udara yang terperangkap dan fenomena buruk yang lain. Akhirnya, beralih ke kedudukan pensuisan tekanan.

Jadual proses pencetakan suntikan

Mesin Pencetakan Suntikan: Haiti 120T, Jenis Skru, Kapasiti Suntikan 150g | Nama Produk: Perlindungan Perlindungan | ||||

Bahan mentah: PC K30 | Warna: Kelabu telus | Suhu pengeringan: 110 ° C. | Kaedah pengeringan: pengering dehumidifikasi | Masa pengeringan: 4 jam | Penggunaan Bahan Kitar Semula: 0 |

Berat produk siap: 10.16g × 2 = 20.32g | Berat Nozzle: 5.8g | Output acuan: 1 × 2 | Kaedah menuangkan gam ke pintu gerbang: menuangkan gam ke dalam air | ||

Suhu barel | Suhu acuan | Gunakan mesin | "Tetapan | "Sebenarnya | ||||

| 1 | 2 | 3 | 4 | 5 | sebelumnya | Mesin suhu malar | 110 ° C. | 105° C. |

| 310 ° C. | 300° C. | 290° C. | 240° C. | 80° C. | ||||

| △ | △ | △ | △ | △ | selepas | Mesin suhu malar | 95° C. | 92° C. |

| △ | △ | △ | △ | △ | ||||

| / | 90 | 95 | Memegang tekanan | 100 | 105 | 115 | 115 | Tekanan suntikan | |

| / | 1.0 | 1.1 | Holding pressure time | 20 | 30 | 30 | 40 | Injection velocity | |

Residual amount of injection glue | / | 10 | 10 | Pressure-holding position | 13 | 13 | 34 | Velocity of fire position | |

| 7.8 | / | / | / | / | 2.0 | Velocity of fire time |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 3.5 | 24 | 45 | 5 | 10 15 10 | 10 | 40 | 3 |

Mold closing time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 120 | 45 | 1 | 15 35 38 | / | / |

Motosikal Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

The mold is charred.

Phenomenon: During the production process of injection molded products, there is often a phenomenon of charring and blackening near the very end.

Analysis: High speed will cause material melting, intensify shearing, generate high temperatures and be prone to decomposition. The surface of the mold is smooth. If the shooting speed is fast, it is prone to high temperature and decomposition. The position switch was too late.

(1) Ciri -ciri mesin pengacuan suntikan

Grade: Haitian, Clamping force: 86t, Plasticizing capacity: 119g.

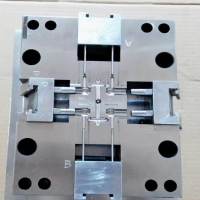

(2) Ciri -ciri acuan

Mold ejection number: 1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 110°C (constant temperature machine)

(3) Ciri -ciri produk

Material: ABS, Color: Gray, Product weight (single piece) : 3.09g, sprue weight: 3.15g

(4) analisis penyebab kecacatan

The main channel of the mold is very large, and the glue inlet method is submersible glue inlet. When the molten material flows near the glue inlet, due to the excessive speed and the very smooth surface of the mold, high shear occurs, causing the molten material to heat up rapidly in an instant. The gas produced by the decomposition of raw materials cannot be discharged in time, resulting in charring.

(5) Penangguhan

1. Menggunakan suntikan pelbagai peringkat dan penukaran kedudukan.

2. In the first stage, use a moderate injection speed to just fill the runner opening to the glue inlet and find the corresponding switching position. Then, in the second stage, use a slow speed and a very small position to fill the area near the glue inlet. In the third section, fill the mold cavity at a medium speed to 97% to prevent the high-temperature molten rubber from cooling. In the fourth section, fill the mold cavity at a slow speed to completely expel the air inside the cavity, avoiding trapped air and charring and other adverse phenomena. Finally, switch to the pressure-holding switching position.

Jadual proses pencetakan suntikan

Injection molding machine: HTAN 86T, Type B screw, injection volume 119g | Product Name: Switch Lever | ||||

Bahan Mentah: Abs PA757 | Colour: Grey | Suhu pengeringan: 85 ° C. | Kaedah pengeringan: pengering dehumidifikasi | Drying time: 3 hours | Recycled material usage: 10% |

Finished product weight: 3.09g×2=6.18g | Nozzle weight: 3.15g | Output acuan: 1 × 2 | Kaedah Suntikan Pintu: Pintu Pintu | ||

Suhu barel | Suhu acuan | Gunakan mesin | "Tetapan | "Sebenarnya | ||||

| 1 | 2 | 3 | 4 | 5 | sebelumnya | Mesin suhu air | 110 ° C. | 98° C. |

| 245°C | 240° C. | 230° C. | 220° C. | / | ||||

| △ | △ | △ | △ | △ | selepas | Mesin suhu air | 110° C. | 96° C. |

| △ | △ | △ | △ | △ | ||||

| / | 89 | Memegang tekanan | Pressure-holding position | 80 | 110 | 120 | Tekanan suntikan | ||

| / | 1.5 | Holding pressure time | 13 | 12 | 13.7 | 18 | Injection pressure position | ||

Residual amount of injection glue | / | 10 | / | 55 | 3 | 7 | 9 | Injection velocity | |

| 10.3 | / | / | / | 12 | 12 | 13.7 | 18 | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 1.6 | 9 | 19.6 | 3 | 40 55 43 | 10 | 22 | 1.5 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 600KN | 45 | 1 | 15 22 23.5 | / | / |

Komoditi Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

Maklumat Berkaitan

Dari pembangunan adat kepada bekalan global, membuka kunci daya penggerak teras pembuatan moden

2025-07-19

Dari pembangunan adat kepada bekalan global, buka kunci daya penggerak teras...

Lukisan acuan dan pengunduran pintu gerbang

2025-08-05

Lukisan acuan dan penipisan fenomena lukisan gatemold: ...

Tentukan paradigma baru untuk industri acuan suntikan melalui penemuan teknologi dan pembinaan semula ekologi

2025-07-04

Menentukan paradigma baru untuk industri acuan suntikan melalui...

Meneroka acuan suntikan: asas ketepatan pembuatan perindustrian

2025-07-11

Meneroka acuan suntikan: asas ketepatan pembuatan industri...

Bahagian acuan standard

2025-07-24

Bahagian standard acuan acuan acuan rangka acuan standard acuan standard ...

Penetapan tekanan pencetakan dan parameter aliran suntikan

2025-07-26

Penetapan tekanan pencetakan suntikan dan parameter aliran1.Setting suntikan ...