Pandangan mendalam dalam industri acuan suntikan: lelaran teknologi, landskap pasaran, dan paradigma baru untuk pembangunan mampan

Pandangan mendalam dalam industri acuan suntikan: lelaran teknologi, landskap pasaran, dan paradigma baru untuk pembangunan mampan

I. Landskap Perindustrian Global: Peralihan tumpuan dan persaingan dan kerjasama serantau

(1) "Mengimbangi" Fokus Pembuatan

Sepanjang dekad yang lalu, industri acuan suntikan telah mengalami peralihan dari "didorong oleh kos" kepada "dwi-dwi oleh teknologi dan kos". Kelompok perindustrian yang diwakili oleh Taizhou dan Dongguan di China telah terus meningkat dalam bahagian pasaran acuan sederhana dan mewah, bergantung kepada "sokongan rantaian perindustrian penuh + dividen jurutera + keupayaan pembuatan fleksibel". Pada tahun 2023, nilai eksport acuan dari Taizhou meningkat sebanyak 18% tahun ke tahun, dengan kadar acuan automotif melebihi 35%, memecahkan halangan teknologi jangka panjang Jerman dan Jepun dalam bidang ini.

Sebaliknya, rumah kuasa acuan tradisional, Jerman, telah melihat kos yang tinggi untuk pesanan kecil dan sederhana kerana "pelaburan yang berlebihan dalam automasi" semasa transformasi industri 4.0. Jepun, yang terjejas oleh penduduk yang semakin tua, mempunyai kekurangan 20% juruteknik acuan, dan bahagian pasarannya terkikis oleh entiti pembuatan yang muncul seperti China dan Vietnam. Walau bagaimanapun, perlu diperhatikan bahawa Jerman masih mengekalkan kelebihan teknologi mutlak dalam acuan ultra-ketepatan gred aerotif (toleransi <0.005mm), dan Jepun dalam acuan lensa optik (kekasaran permukaan RA <0.01μm), dengan itu membentuk corak kompetitif global yang baru "mengunci aliran tinggi dan pertengahan aliran".

(2) Permintaan pembezaan di pasaran serantau

Pasaran Amerika Utara disebabkan oleh pertumbuhan kenderaan tenaga baru yang meletup (seperti Tesla dan Rivian) dan peralatan perubatan (seperti Boston Scientific), permintaan untuk acuan suntikan jangka hayat dan cepat berubah. Jumlah pesanan pada Q1 2024 meningkat sebanyak 22% berbanding tempoh yang sama tahun lepas. Dan mereka sanggup membayar premium (purata 15% - 20%) untuk perkhidmatan sehenti "pembuatan kontrak pengeluaran massa + acuan".

Pasar Eropah yang didorong oleh peraturan perlindungan alam sekitar (seperti REACH dan versi ROHS 2.0 yang dinaik taraf), keperluan teknikal untuk acuan bahan biodegradable (seperti acuan suntikan PLA dan PHA) adalah ketat. Rawatan permukaan acuan mesti memenuhi piawaian ganda "tiada sisa kimia + ketahanan terhadap kakisan biologi", yang telah menimbulkan model pembangunan bersama "reka bentuk acuan + penyelidikan dan pembangunan bahan".

Pasar Asia Tenggara dengan pengembangan pengeluar kontrak elektronik (seperti kilang Vietnam Samsung dan pangkalan Indonesia Xiaomi), terdapat permintaan yang kukuh untuk asas acuan standard prestasi tinggi dan penghantaran cepat. Perusahaan acuan Cina telah mencapai "bulatan penghantaran acuan 72 jam" dengan menubuhkan gudang terikat di Vietnam dan barisan pemasangan di Thailand. Walaupun harga purata acuan yang dieksport ke ASEAN menurun sebanyak 8% pada tahun 2023, jualan meningkat sebanyak 37%. Ia membentangkan ciri -ciri "keuntungan tipis tetapi jumlah jualan yang tinggi + penembusan pasaran".

Kereta Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

Ii. Inovasi Teknologi: Empat trend teras membentuk semula industri acuan

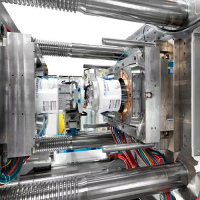

(1) acuan pintar: dari "tindak balas pasif" hingga "evolusi aktif"

Acuan tradisional adalah alat pengeluaran, sementara acuan pintar telah menjadi "terminal data + nod membuat keputusan". Dengan memasukkan sensor tekanan, sensor suhu, dan alat pengukur terikan (seperti sensor mikro HBM Jerman yang boleh diintegrasikan ke dalam teras acuan tebal 5mm) dalam acuan, lebih daripada 200 parameter proses semasa proses pengacuan suntikan dapat dikumpulkan dalam masa nyata. Digabungkan dengan algoritma AI (seperti model ramalan proses yang dilatih oleh tensorflow), ia mencapai:

Ramalan Kekurangan: Mengeluarkan amaran awal tiga kitaran sebelum kecacatan seperti kilat dan pukulan pendek berlaku, mengurangkan kadar kecacatan ke bawah 0.5% (kadar kecacatan acuan tradisional adalah kira -kira 3% - 5%).

Pelarasan parameter yang dioptimumkan sendiri: Secara automatik menyesuaikan tekanan pegangan dan masa penyejukan berdasarkan turun naik bahan-bahan (seperti sisihan indeks PP cair ± 0.5g/10min), meningkatkan kestabilan proses sebanyak 40%.

Ramalan Hidup: Berdasarkan model kembar digital acuan memakai, dengan tepat meramalkan kehidupan rongga acuan dan gelangsar, mengurangkan kos penyelenggaraan acuan sebanyak 25%.

Kes tipikal: Haier Acuan menyesuaikan acuan laci peti sejuk pintar untuk perusahaan perkakas rumah tertentu. Dengan secara langsung menghubungkan sensor dalam acuan dengan sistem MES kilang, keseluruhan proses dari "penempatan pesanan ke penghantaran produk siap" tidak dapat dikendalikan sepenuhnya, meningkatkan kecekapan pengeluaran sebanyak 30% dan mengurangkan kos acuan komprehensif sebanyak 22%.

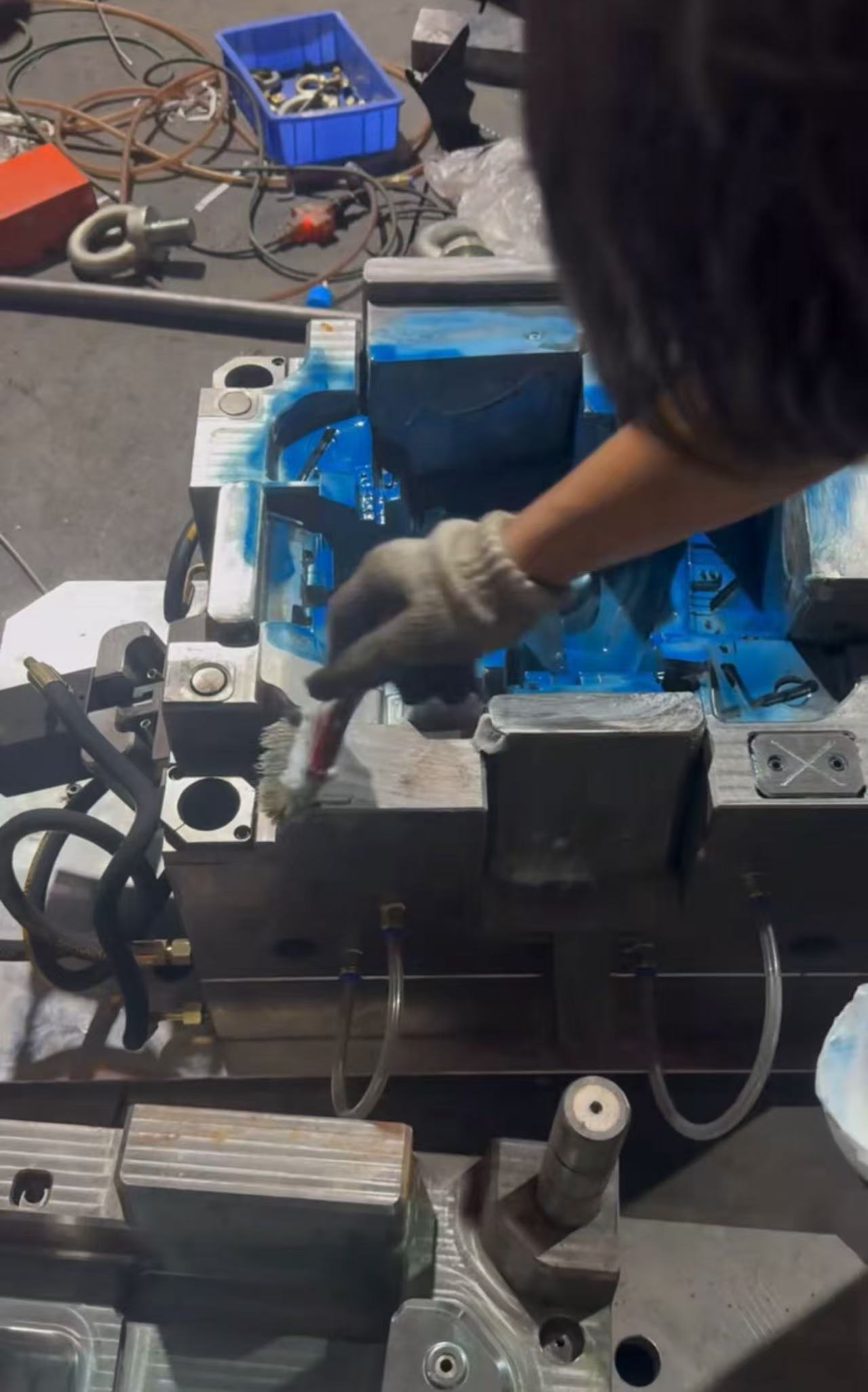

(2) Revolusi Bahan: "Battlefield Baru" melepasi sempadan prestasi

Bahan acuan telah beralih dari "pergantungan pada gred keluli tunggal" ke inovasi komposit "bahan komposit + salutan berfungsi":

Bahan asas: Serbuk generasi ketiga keluli berkelajuan tinggi (seperti versi dinaik taraf ASP-60), dengan pengedaran karbida yang lebih seragam, mengekalkan kekerasan (HRC 62-64) sambil meningkatkan ketangguhan sebanyak 30%, dan kehidupan suntikan PA6 + 30%gf) melampaui 500,000 cucian. Komposit matriks aluminium (al-SIC) telah melihat kadar permohonan mereka dalam acuan suntikan berdinding nipis (seperti acuan kes telefon bimbit dengan ketebalan dinding 0.5mm) meningkat kepada 18% kerana ringan (dengan ketumpatan hanya 1/3 dari keluli)

Rawatan permukaan: Salutan berlian (seperti pemendapan wap kimia CVD berlian) meningkatkan kekerasan permukaan acuan hingga 10,000hv, dan rintangan haus dipertingkatkan sebanyak 10 kali. Dalam pencetakan suntikan plastik kejuruteraan suhu tinggi seperti LCP (polimer kristal cecair), kehidupan acuan telah melonjak dari 50,000 kitaran kepada 300,000 kitaran. Lapisan nano-seramik (seperti salutan komposit Al₂o₃ -tio ₂) mencapai "pelinciran diri + rintangan kakisan kimia". Dalam pengacuan suntikan fluoroplastik (seperti PTFE), daya demolding dikurangkan sebanyak 60%, menyelesaikan masalah "melekat" lama yang telah melanda industri.

(3) Pembuatan Aditif: "Tambahan Supresi" untuk pembuatan acuan

Percetakan 3D telah berpindah dari "pengesahan prototaip" ke peringkat "pengeluaran besar -besaran". Teknologi yang diwakili oleh SLM (pencairan laser selektif) dan MJF (Multi-Jet Pencengang) telah mencapai tiga kejayaan utama dalam pembuatan acuan:

Saluran air penyejuk konformal: Saluran air gerudi tradisional mempunyai kecekapan penyejukan yang rendah (perbezaan suhu acuan ± 5 ℃). Saluran air conformal yang dicetak 3D boleh membuat perbezaan suhu acuan ≤1 ℃, memendekkan kitaran pencetakan suntikan sebanyak 20% - 30%. Melalui reka bentuk saluran air conformal, kitaran pengeluaran acuan lampu automotif tertentu dikurangkan dari 45 saat hingga 32 saat.

Integrasi Struktur Kompleks: Struktur "slider hollow + bersarang sisipan" tanpa memerlukan splicing mengurangkan bilangan bahagian acuan sebanyak 40% dan memendekkan masa pemasangan sebanyak 50%. Sebagai contoh, dalam acuan rod push suntikan perubatan, pemasangan slider 12 bahagian asal dibentuk dalam satu bahagian selepas percetakan 3D.

Pembaikan acuan cepat: Apabila produk berulang, percetakan 3D dapat menyelesaikan pengubahsuaian acuan tempatan hanya dalam 24 hingga 48 jam, dengan kos yang hanya satu pertiga daripada pembaikan acuan pelepasan elektrik tradisional. Kitaran lelaran produk baru perusahaan elektronik pengguna tertentu telah dimampatkan dari 3 bulan hingga 45 hari.

However, it should be viewed objectively: At present, 3D printed molds are still limited in the fields of large size (> 1m molds) and ultra-high precision (tolerance < 0.01mm), and the cost of printing materials (such as nickel-based alloys and titanium alloys) is 5 to 8 times that of traditional mold steel. In the short term, it is a "supplement to traditional manufacturing" rather than a "replacement".

(4) Sustainable Molds: A "Must-Answer Question" for Green Transformation

The global carbon neutrality goal is compelling the mold industry to adopt a dual-track approach of "carbon reduction and recycling" :

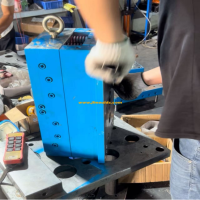

Carbon reduction at the manufacturing end: The adoption of dry cutting (replacing emulsion cooling) reduces carbon emissions in the mold processing stage by 40%. The EcoTurn machine tool series launched by German DMG MORI reduces carbon emissions by 1.2 tons per machine tool per year by optimizing cutting parameters and cooling systems. The lightweight design of molds (such as the use of aluminum alloy mold bases and hollowed-out inserts) reduces raw material consumption by 15% to 20%, and at the same time lowers the demand for clamping force of injection molding machines (for every 100kg reduction in mold weight, the energy consumption of injection molding machines is reduced by 3%).

Loop end innovation The mold Remanufacturing industry has emerged. Through the process of "inspection - repair - upgrade", the performance of used molds can be restored to over 90% of that of new molds, with the cost being only 50% to 70% of that of new molds. The number of mold remanufacturing orders on the Xometry platform in the United States increased by 55% in 2023. Bio-based mold materials (such as polylactic acid (PLA) -based composites) account for up to 10% of low-load molds (such as stationery and toy molds), and their life cycle carbon emissions are 65% lower than those of traditional plastic molds.

Motosikal Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

Iii. The Breakthrough Path for Chinese Mold Enterprises: Opportunities and Challenges

(1) Technological Breakthrough: The Crucial Battle from "Following" to "Leading"

Chinese mold enterprises have achieved technological leadership in fields such as new energy vehicle battery tray molds (large-scale + integrated), 5G base station shell molds (thin-walled + high-rigidity), and photovoltaic frame molds (weather-resistant + low-cost).

Battery tray mold: NIO's 1500mm×2000mm super-large integrated battery tray mold adopts a "molding + injection molding" composite process, reducing the weight of the tray by 25% and increasing production efficiency by 40%, breaking the foreign monopoly on molds for large structural components.

5G base station mold: The 0.8mm wall thickness base station shell mold developed by Huawei's supplier, through the "air-assisted injection molding + in-mold decoration (IMD)" technology, realizes the integrated molding of appearance parts and structural parts, increasing the yield rate from 60% to 92%.

Photovoltaic frame mold: The ASA co-extruded photovoltaic frame mold developed by the supporting mold enterprise of Tongwei Co., Ltd. has solved the pain points of traditional PVC frames such as "poor weather resistance and difficult recycling". The mold life (under outdoor ultraviolet irradiation environment) has exceeded 80,000 mold times, promoting the recycling rate of photovoltaic modules to increase to 85%.

(2) Brand Building: Breaking Away from the cognitive battle of the "low-cost Label"

For a long time, the overseas perception that "Chinese molds = low price and low quality" urgently needs to be reversed. Leading enterprises are reshaping their brands through a combination of "technology patents + industry standards + benchmark cases"

Patent layout: The mold division of Haitian International has cumulatively applied for over 800 patents, among which more than 20 patents such as "Multi-Component Injection Molding Synchronous Forming Technology" have filled international gaps.

Standard formulation: Participated in the formulation of 10 international standards such as ISO 20430 "General Technical Requirements for Plastic Injection Molds", and incorporated "Chinese process parameters" into global guidelines;

Case output: The Watch band molds provided to Apple's supply chain achieved a "0.05mm tolerance + 500,000 mold life", setting a benchmark for mold quality in the consumer electronics field and driving a 30% increase in brand premium.

(3) Supply Chain Security: Tackling the "Bottleneck" Links

Although China's mold industry accounts for 40% of the global scale, it still relies on imports in high-end mold steel (such as Dievar steel from SSAB in Sweden), precision hot runner systems (such as Husky in the United States), and micro-sensors (such as HBM in Germany), highlighting supply chain risks. The paths to break the deadlock include

Material autonomy: The "RH refining of die steel + electroslag remelting" process developed by Baosteel Special Steel has brought the performance of domestic DC53 steel close to that of similar products from Daido Steel of Japan, and it has been applied in batches in 3C molds.

Core component substitution: The hot runner system independently developed by Haitian Plastic Machinery has a flow control accuracy of ±1% (±0.5% at the international first-class level), and its substitution rate in the mid-range mold market exceeds 60%.

Industry-university-research collaboration: The State Key Laboratory of Mold Technology at Huazhong University of Science and Technology and Dongguan Jingsheng Intelligent jointly established the "Precision Mold Joint Research and Development Center", overcoming the "micron-level mold surface Texching" technology, which has improved the mold demolding performance by 50%.

Iv. The Next Five Years: Six Predictions for Industrial Evolution

1.The "mold-as-a-Service" model has exploded: Mold enterprises have shifted from "selling products" to "selling production capacity + selling technology + selling data", such as providing a full-cycle Service of "mold leasing + charging per mold + process management", which has been first implemented in fields like medical care and auto parts.

2. The "cross-industry technology integration" is accelerating: Drawing on the "topology optimization" of aerospace and the "bionic design" of biomedicine, mold structures will become lighter and more functional. For instance, the mold for automotive bumpers that imitates the honeycomb structure will reduce its weight by 35% while increasing its strength by 20%.

3. The rise of "regional mold ecosystem" : Besides Taizhou and Dongguan, the Chengdu-Chongqing region (relying on the automotive industry) and the northern wing of the Yangtze River Delta (Nantong and Taizhou, connecting with Shanghai's high-end manufacturing) will form new growth poles for the mold industry, with the supporting rate within the region increasing to over 80%.

4. "AI Full-chain Penetration" : From mold Design (Generative Design for automatically generating the optimal structure), manufacturing (AI production scheduling + tool path optimization) to operation and maintenance (predictive maintenance), AI makes it possible to increase the efficiency of the mold industry by 50%.

5. "Technological Reshuffling driven by environmental protection regulations" : The EU's "carbon border tax" and the US "Clean Manufacturing Act" will eliminate a batch of small and medium-sized mold enterprises that fail to meet environmental protection standards, raising the industry concentration (CR10) from the current 15% to over 30%.

6. "Reshaping the talent structure" : The collaboration between mold technicians and algorithm engineers as well as material scientists has become routine. There is a shortage of 500,000 compound talents in "mold + digitalization + new materials", and the reform of vocational education (such as the localization of the German dual system) is extremely urgent.

V. "Long-termism" in the Mold Industry

Injection molds, as the core link of the "mother of industry", have long surpassed the scope of "tool manufacturing" in their development, becoming a comprehensive manifestation of a country's manufacturing competitiveness, technological innovation capacity, and sustainable development ability. Only by adhering to "in-depth technological development + brand upgrading + ecological co-construction" can China's mold industry take the initiative in the global industrial restructuring and move from a "major mold country" to a "powerful mold country". In the future, every milling mark on a mold will bear the era's imprint of China's manufacturing industry's upgrading.

Maklumat Berkaitan

Reka bentuk inovatif dan trend pembangunan pintar acuan suntikan

2025-07-09

Reka bentuk inovatif dan trend pembangunan pintar acuan suntikan dalam...

Dalam kedalaman Deconstruction industri acuan suntikan: kejayaan teknologi, pembinaan semula pasaran dan peningkatan dimensi ekologi

2025-07-03

Dalam kedalaman Deconstruction industri acuan suntikan: teknologi...

Industri acuan suntikan: memecahkan halangan teknologi dan merampas trek baru pembuatan pintar

2025-07-01

Industri acuan suntikan: memecahkan halangan teknologi dan...

Acuan suntikan: pembuatan khusus, memperkasakan produktiviti kualiti baru dalam industri

2025-07-14

Acuan suntikan: pembuatan khusus, memperkasakan produktiviti kualiti baru...

Analisis mendalam acuan suntikan: penerokaan proses penuh dari reka bentuk ke aplikasi

2025-07-10

Analisis dalam kedalaman acuan suntikan: penerokaan proses penuh dari reka bentuk ke...

Wawasan panorama ke dalam industri acuan suntikan: maju ke hadapan dalam gelombang perubahan

2025-07-04

Wawasan panorama ke dalam industri acuan suntikan: maju ke hadapan dalam gelombang...