Reka bentuk inovatif dan trend pembangunan pintar acuan suntikan

Reka bentuk inovatif dan trend pembangunan pintar acuan suntikan

Pencetakan suntikan, sebagai salah satu teknologi pemprosesan yang paling banyak digunakan dalam pembuatan moden, tahap teknikal pembawa terasnya, acuan suntikan, secara langsung menentukan kualiti produk, kecekapan pengeluaran dan kos pembuatan. Dengan kemunculan bahan -bahan baru, proses baru dan teknologi baru, industri acuan suntikan sedang menjalani tempoh transformasi kritikal dari pembuatan tradisional kepada pembuatan pintar, tepat dan hijau. Artikel ini secara sistematik akan meneroka teknologi canggih dan penemuan praktikal dalam bidang acuan suntikan dari aspek seperti reka bentuk inovatif struktur acuan, penerapan bahan-bahan baru, teknologi pembuatan pintar, konsep pengeluaran hijau, dan trend pembangunan masa depan, memberikan idea dan rujukan baru untuk pembangunan industri.

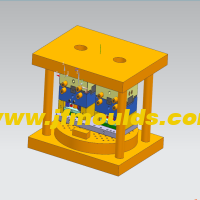

Pengilang Aksesori Crossbeam Radiator Automobil di China (JFMoulds.com)

I. Petunjuk terobosan untuk reka bentuk struktur acuan suntikan yang inovatif

Reka bentuk struktur acuan suntikan adalah faktor teras yang menentukan kualiti pencetakan. Struktur acuan tradisional sering menghadapi masalah seperti kecekapan yang rendah dan kestabilan yang lemah apabila berurusan dengan bentuk geometri yang kompleks, keperluan ketepatan tinggi, atau pencetakan bahan khas. Dalam tahun -tahun kebelakangan ini, industri telah menyaksikan kemunculan banyak teknologi terobosan dalam inovasi struktur, dengan berkesan menangani titik kesakitan reka bentuk tradisional.

1. Reka bentuk saluran air penyejuk konformal dan aplikasi pembuatan tambahan

Saluran air penyejuk acuan tradisional kebanyakannya struktur lurus atau mudah melengkung, yang sukar dipadankan dengan bentuk kompleks bahagian plastik, mengakibatkan masalah seperti penyejukan yang tidak sekata, kitaran pencetakan panjang, dan melengkapkan dan ubah bentuk bahagian plastik. Reka bentuk saluran air penyejuk conformal mensimulasikan pengagihan medan suhu bahagian plastik melalui kejuruteraan dibantu komputer. Ia mengamalkan struktur saluran air melengkung tiga dimensi selari dengan kontur permukaan bahagian plastik, yang membolehkan medium penyejukan mengalir secara merata melalui semua bahagian bahagian plastik dan meningkatkan kecekapan penyejukan dengan ketara.

Kematangan teknologi pembuatan bahan tambahan menyediakan kemungkinan untuk memproses saluran air penyejuk konformal. Dengan mengadopsi teknologi lebur laser terpilih, teras dan rongga acuan boleh secara langsung sintered, mengintegrasikan saluran air konformal yang kompleks di dalam acuan tanpa memerlukan splicing atau proses penggerudian dalam pemprosesan tradisional. Amalan perusahaan bahagian auto tertentu menunjukkan bahawa penggunaan penyejukan konformal untuk acuan bumper telah mengurangkan masa penyejukan dari 60 saat asal hingga 35 saat, meningkatkan kecekapan pengeluaran sebanyak 40%. Pada masa yang sama, peperangan bahagian plastik dikawal dalam 0.1mm, dan kadar sekerap telah menurun sebanyak 60%.

2. Reka bentuk struktur acuan modular dan cepat berubah

Sebagai tindak balas kepada tuntutan pengeluaran pelbagai jenis dan kelompok kecil, reka bentuk acuan modular membolehkan beralih cepat di antara bahagian plastik yang berbeza dengan menguraikan acuan ke dalam modul standard seperti asas acuan asas, rongga/teras yang boleh diganti, dan mekanisme penarik teras. Modul-modul ini disambungkan oleh pin kedudukan ketepatan tinggi dan peranti mengunci untuk memastikan ketepatan pemasangan selepas acuan berubah. Selepas perusahaan perkakas rumah tertentu mengguna pakai acuan modular untuk barisan pengeluaran panel mesin basuh, masa perubahan acuan dipendekkan dari tradisional 2 jam hingga 15 minit, dan kadar penggunaan peralatan meningkat sebanyak 25%.

Teknologi perubahan acuan yang cepat juga termasuk sistem perubahan acuan automatik yang didorong oleh hidraulik/pneumatik. Melalui hubungan sensor dan sistem kawalan, ia menyedari pengenalan automatik, kedudukan dan pengapit acuan. Memasang peranti dibantu robot di antara mesin pengacuan suntikan dan acuan dapat mengurangkan intervensi manual dan membolehkan proses perubahan acuan sepenuhnya automatik.

3. Inovasi dalam acuan berpisah dan mekanisme penarik teras untuk rongga kompleks

Bagi bahagian plastik dengan struktur kompleks seperti rongga yang mendalam, lubang terbalik, dan lubang sampingan, mekanisme teras tradisional sering mempunyai masalah seperti struktur kompleks, gangguan gerakan, atau daya teras yang tidak mencukupi. Dalam tahun-tahun kebelakangan ini, industri telah membangunkan pelbagai penyelesaian teras inovatif:

Mekanisme teras-teras berlapis: Melalui reka bentuk teras bersarang berbilang lapisan, ia menyadari teras-teras berlapis bahagian plastik rongga yang mendalam, mengelakkan kerosakan pada bahagian-bahagian plastik yang disebabkan oleh tindakan teras yang menarik. Acuan shell luar set infusi perusahaan peranti perubatan tertentu mengamalkan tiga lapisan yang ditumpuk teras-tarik, berjaya menyelesaikan masalah teras yang menarik dari struktur tiub dengan kedalaman sehingga 120mm.

Mekanisme komposit teras teras dan berputar yang cenderung: ia menggabungkan gerakan linear bahagian atas yang cenderung dengan gerakan pekeliling teras teras berputar, dan sesuai untuk bahagian plastik dengan alur helical atau lekukan sampingan yang kompleks. Antara muka berulir yang membentuk shell pengecas telefon bimbit sering mengamalkan struktur ini untuk memastikan ketepatan benang mencapai gred ISO 4H.

Sistem penarik teras yang fleksibel: Ia mengamalkan lengan mekanikal berbilang darjah yang didorong oleh motor servo sebagai penggerak teras. Dengan mengawal laluan teras melalui program, ia boleh menyesuaikan diri dengan perubahan struktur minit dari kumpulan plastik yang berlainan dan sangat sesuai untuk pengeluaran yang disesuaikan.

4. Pengoptimuman pelari untuk acuan suntikan pelbagai bahan

Multi-bahan pengacuan suntikan boleh mencapai acuan bersepadu bahagian plastik bahan, warna atau sifat yang berbeza dalam acuan yang sama, mengurangkan proses pemasangan berikutnya. Inti struktur acuannya terletak pada reka bentuk sistem pelari, yang memerlukan kawalan tepat urutan pengisian, nisbah aliran dan integrasi antara muka pelbagai bahan.

"Runner Switching Dynamic" yang inovatif mengawal masa suntikan bahan -bahan yang berbeza melalui injap solenoid, dan digabungkan dengan reka bentuk pintu kecerunan, ia membolehkan kedua -dua bahan membentuk struktur berlapis seragam dalam rongga. Kes smartwatch perusahaan elektronik tertentu dibuat oleh pengacuan bersama ABS dan TPU. Melalui pengoptimuman saluran aliran, kekuatan ikatan kedua -dua bahan telah meningkat kepada 25MPa, jauh melebihi 15MPA struktur tradisional. Di samping itu, untuk acuan berputar pelbagai warna, plat pembahagian ketepatan tinggi digunakan untuk mengawal sudut putaran rongga, memastikan sempadan yang jelas dari pewarna dan mengelakkan kecacatan pencampuran warna.

Pengilang acuan dulang di China (jfmoulds.com)

Ii. Kemajuan aplikasi bahan acuan baru dan teknologi rawatan permukaan

Prestasi bahan acuan secara langsung mempengaruhi hayat perkhidmatan, membentuk ketepatan dan kos pembuatan acuan. Dengan permintaan yang semakin meningkat untuk membentuk bahan -bahan khas seperti suhu tinggi, keterujaan yang tinggi dan kadar pengisian yang tinggi, keluli mati tradisional telah menjadi sukar untuk memenuhi keperluan. Penggunaan bahan -bahan baru dan teknologi rawatan permukaan telah menjadi arahan penting bagi pembangunan industri.

Penyelidikan dan penggunaan keluli mati berprestasi tinggi

Keluli mati tradisional seperti CR12 dan S136 mempunyai masalah prestasi individu yang cemerlang dari segi kekerasan, rintangan haus atau rintangan kakisan, tetapi prestasi keseluruhan yang tidak mencukupi. Dalam tahun-tahun kebelakangan ini, perusahaan keluli domestik dan asing telah membangunkan pelbagai keluli mati aloi berprestasi tinggi. Melalui pengoptimuman komposisi dan peningkatan proses rawatan haba, mereka telah mencapai kejayaan dalam prestasi komprehensif.

Serbuk Metalurgi keluli berkelajuan tinggi: keluli mati ASP-60 yang dihasilkan oleh proses metalurgi serbuk, dengan unsur-unsur aloi seperti kandungan tungsten, molibdenum dan vanadium mencapai lebih dari 15%. Selepas rawatan haba, kekerasannya dapat mencapai HRC 65-67, dan rintangan hausnya adalah tiga kali dari keluli CR12 tradisional. Ia sesuai untuk memproses plastik bertetulang dengan gentian kaca tambahan. Selepas acuan enjin kereta tertentu mengamalkan bahan ini, hayat perkhidmatannya meningkat daripada 500,000 kitaran kepada 1.5 juta kitaran.

Keluli tahan karat martensit yang tahan karat: seperti keluli 718h, dengan meningkatkan kandungan unsur kromium dan nikel dan menggunakan rawatan ultra-halus, ia dapat mengekalkan kekerasan HRC 50-52 sambil mencapai rintangan kakisan garam lebih dari 5000 jam, menjadikannya sesuai untuk pencabulan.

Keluli berkekuatan tinggi suhu rendah: Selepas rawatan kriogenik yang mendalam, kandungan austenit sisa di dalam keluli stavax ESR dikurangkan kepada di bawah 5%. Pada suhu bilik, kekuatan tegangannya mencapai 1800MPa, dan ia masih dapat mengekalkan sifat mekanik yang stabil dalam persekitaran suhu rendah sebanyak -50 ℃. Ia sesuai untuk acuan plastik kejuruteraan yang dibentuk pada suhu rendah.

2. Aplikasi inovatif bahan acuan bukan logam

Dalam bidang pengeluaran kecil atau pembuatan prototaip, acuan bahan bukan logam telah digunakan secara meluas kerana kelebihan kos rendah dan kitaran pendek. Dalam tahun-tahun kebelakangan ini, prestasi bahan komposit dan acuan plastik kejuruteraan telah terus meningkat, secara beransur-ansur menembusi bidang pengeluaran medium-batch:

Resin epoksi bertetulang serat karbon: Dibentuk oleh cetakan komposit serat karbon dan resin epoksi, berat acuan hanya 1/5 daripada acuan keluli tradisional. Kekonduksian terma boleh diselaraskan kepada 15-20 w/(m · k) dengan menambahkan graphene, menjadikannya sesuai untuk pencetakan tekanan rendah plastik thermosetting. Acuan shell luar kenderaan udara yang tidak dikendalikan oleh Aeroangkasa Aeroangkasa mengamalkan bahan ini, mengurangkan kos pembuatan sebanyak 60% dan memendekkan kitaran pengeluaran dari 45 hari hingga 15 hari.

Kejuruteraan berasaskan PEEK acuan plastik: mengintip (polyetheretherketone) mempunyai rintangan suhu tinggi dan rintangan kakisan kimia. Dengan menambahkan mikrosfera kaca, pekali pengembangan linear boleh dikawal di bawah 8 × 10^-6/℃, menjadikannya sesuai untuk membentuk suntikan bahagian plastik kecil. Cetakan jarum suntikan pakai pakai dari perusahaan peralatan perubatan tertentu diperbuat daripada bahan mengintip. Kos satu set acuan hanya 1/10 daripada acuan keluli, dan ia dapat memenuhi permintaan pengeluaran sebanyak 10,000 hingga 50,000 acuan.

3. Teknologi Rawatan Permukaan Lanjutan meningkatkan prestasi acuan

Teknologi rawatan permukaan dapat meningkatkan rintangan haus, rintangan kakisan, sifat demolding dan sifat lain acuan dengan membentuk lapisan khas atau lapisan yang diubahsuai pada permukaan acuan, sambil mengurangkan kos pengeluaran. Dalam tahun -tahun kebelakangan ini, inovasi dalam bidang rawatan permukaan dalam industri telah memberi tumpuan kepada aspek berikut:

Pemendapan wap fizikal (PVD) salutan super-keras: Dengan menggunakan teknologi penyaduran ion multi-arka untuk mendepositkan salutan seperti TIALN dan CRN pada permukaan acuan, ketebalan dikawal pada 3-5μm, kekerasan dapat mencapai HV 2500-3000, dan koefisien geseran dikurangkan ke bawah 0.2. Selepas acuan cetakan botol tertentu menggunakan salutan TiALN, daya demolding acuan dikurangkan dari 80N asal hingga 35N, menghapuskan keperluan untuk ejen pelepasan acuan dan mengelakkan pencemaran permukaan bahagian plastik.

Salutan berlian pemendapan wap kimia (CVD): salutan berlian polikristalin didepositkan pada permukaan acuan melalui teknologi CVD dawai panas, dengan kekerasan setinggi HV 10000 dan kekonduksian terma 800 w/(m · k), menjadikannya sesuai untuk memproses plastik yang diperkuatkan dengan kadar pengisian yang tinggi. Data eksperimen menunjukkan bahawa hayat perkhidmatan acuan yang disalut dengan berlian adalah 10 hingga 15 kali dari acuan yang tidak bersalut.

Rawatan Tekstur Permukaan Laser: Dengan menggunakan laser femtosecond untuk memproses lubang mikron (5-50μm) atau struktur jalur pada permukaan rongga acuan, "tangki penyimpanan minyak" atau "lapisan filem gas" terbentuk, yang dapat mengurangkan pekali geseran lebih daripada 50%. Untuk membentuk bahan-bahan kelikatan tinggi seperti PC (polikarbonat), rawatan tekstur dapat mengurangkan tekanan suntikan sebanyak 15% hingga 20% dan mengurangkan tekanan dalaman bahagian plastik.

Salutan seramik sol-gel: salutan seramik komposit SiO2-Al2O3 terbentuk pada permukaan acuan melalui kaedah sol-gel, dengan ketebalan 1-2μm. Ia mempunyai rintangan kakisan yang sangat baik dan tidak melekat, dan sesuai untuk membentuk bahan-bahan yang mudah decomposable seperti PVC dan POM. Selepas acuan paip saliran PVC dari perusahaan pemasangan paip tertentu mengguna pakai salutan ini, kitaran pembersihan acuan dilanjutkan dari 15 hari hingga 60 hari, dan kestabilan pengeluaran telah meningkat dengan ketara.

Sampah boleh acuan pengeluar di China (jfmoulds.com)

Iii. Pembuatan pintar dan pengurusan digital acuan suntikan

Kemajuan yang mendalam dari konsep Industri 4.0 dan pembuatan pintar telah mendorong industri acuan suntikan untuk mengubah dari model "pengalaman" tradisional kepada "data yang didorong oleh data". Teknologi Pembuatan Pintar mengintegrasikan teknologi seperti sensor, Internet of Things, dan analisis data yang besar dengan keseluruhan proses reka bentuk acuan, pemprosesan, dan penggunaan, mencapai ketepatan tinggi, kecekapan tinggi, dan pengeluaran kebolehpercayaan tinggi acuan.

Reka bentuk dan simulasi acuan berdasarkan kembar digital

Teknologi kembar digital mencapai simulasi dan pengoptimuman dinamik keseluruhan proses dari reka bentuk, pemprosesan, ujian acuan untuk pengeluaran dengan membina transformasi digital maya acuan. Semasa peringkat reka bentuk, perisian pemodelan 3D digunakan untuk membina model geometri acuan, dan alat simulasi CAE digabungkan untuk mensimulasikan dan menganalisis proses seperti mengisi, memegang tekanan, penyejukan, dan warping.

Simulasi proses pengisian: Dengan mensimulasikan laluan aliran, pengagihan tekanan dan perubahan suhu bahan cair di rongga, kedudukan dan bilangan pintu dioptimumkan. Acuan untuk laci peti sejuk perusahaan perkakas rumah tertentu mengurangkan bilangan pintu dari 4 hingga 2 melalui simulasi, menghapuskan kecacatan tanda kimpalan.

Simulasi Sistem Penyejukan: Kirakan pengagihan medan suhu acuan berdasarkan persamaan pengaliran haba, mengoptimumkan diameter, jarak dan kadar aliran saluran air, dan mengawal perbezaan suhu acuan dalam ± 2 ℃.

Ramalan dan Pampasan Warpage: Berdasarkan data kadar pengecutan bahan, jumlah pampasan terbalik adalah pratetap semasa reka bentuk acuan untuk mengatasi ubah bentuk peperangan bahagian plastik selepas mencetak.

Model kembar digital juga boleh dihubungkan dengan data masa nyata peralatan pengeluaran. Semasa peringkat percubaan acuan, parameter proses boleh dioptimumkan melalui debugging maya, mengurangkan bilangan ujian acuan fizikal. Amalan perusahaan bahagian auto tertentu menunjukkan bahawa selepas mengamalkan teknologi kembar digital, bilangan acuan acuan telah dikurangkan dari tradisional 5 hingga 8 kali hingga 2 hingga 3 kali, memendekkan kitaran pembangunan sebanyak 30%.

2. Integrasi peralatan dan teknik pemprosesan pintar

Pemprosesan ketepatan tinggi bahagian acuan bergantung pada koordinasi peralatan dan teknik pemprosesan pintar. Dalam tahun-tahun kebelakangan ini, tahap kecerdasan pusat pemesinan kaitan lima paksi, penggilingan berkelajuan tinggi, pembentukan pelepasan elektrik dan peralatan lain telah meningkat dengan ketara. Digabungkan dengan teknologi kawalan penyesuaian, pelarasan masa nyata proses pemprosesan telah dicapai.

Pusat Pemesinan Hubungan Lima Paksi: Ia mengamalkan kawalan gelung tertutup penguasa grating dan teknologi pampasan kesilapan terma, dan boleh melengkapkan penggilingan, penggerudian, mengetuk dan lain-lain proses rongga kompleks dalam satu penjepit. Apabila acuan ketepatan tertentu memproses rongga melengkung acuan shell telefon bimbit, kekasaran permukaan dikawal dalam RA 0.05μm, memenuhi keperluan kesan cermin.

Teknologi Pengilangan Berkelajuan Tinggi: Mesin pengilangan berkelajuan tinggi dengan kelajuan gelendong antara 40,000 hingga 60,000 r/min, digabungkan dengan alat karbida bersemangat ultra-halus, boleh mencapai pemotongan kelajuan tinggi keluli mati, dengan kadar penyingkiran material sehingga 500cm³/min, dan kecekapan pemprosesan ultra-berminyak itu tiga kali gandaan tradisional.

Kawalan penyesuaian pembentukan elektrik: Dengan menggunakan sensor untuk memantau jurang pelepasan dan perubahan semasa dalam masa nyata, parameter nadi secara automatik diselaraskan untuk mengelakkan kesilapan dimensi yang disebabkan oleh memakai elektrod yang tidak sekata. Untuk struktur alur yang mendalam dan sempit dalam acuan, ketepatan pemprosesan dapat mencapai ± 0.002mm.

Di samping itu, integrasi sistem pemuatan dan pemunggahan automatik dengan peralatan pemprosesan telah membolehkan pengeluaran berterusan 24 jam, mengurangkan kitaran pemprosesan bahagian acuan sebanyak lebih daripada 40%.

3. Pemantauan keadaan acuan dan penyelenggaraan ramalan

Semasa penggunaan acuan, dengan memasang penderia untuk memantau status operasinya dalam masa nyata dan menggabungkan analisis data besar untuk mencapai penyelenggaraan ramalan, masa henti yang disebabkan oleh kegagalan mengejut boleh dikurangkan dengan ketara. Teknik pemantauan yang biasa digunakan termasuk:

Pemantauan suhu: Termokopel atau penderia suhu inframerah dibenamkan dalam rongga acuan dan teras untuk mengumpul data suhu dalam masa nyata. Penggera dikeluarkan apabila suhu melebihi julat yang ditetapkan untuk mengelakkan kecacatan pada bahagian plastik akibat terlalu panas atau terlalu sejuk.

Pemantauan tekanan: Pasang penderia tekanan di dalam rongga untuk memantau perubahan dalam tekanan suntikan dan tekanan penahan bahan cair, dan segera mengesan masalah seperti tersumbat pada port suapan atau kebocoran acuan.

Pemantauan getaran: Dengan mengumpul isyarat getaran semasa membuka dan menutup acuan melalui penderia pecutan, menganalisis perubahan dalam frekuensi dan amplitud getaran, dan menentukan status haus pin panduan dan lengan panduan.

Pemantauan haus: Penderia anjakan laser digunakan untuk mengimbas permukaan rongga, dan jumlah haus dikira dengan membandingkannya dengan saiz awal. Apabila jumlah haus melebihi 0.01mm, amaran dikeluarkan untuk menghalang pengeluaran besar-besaran bahagian plastik substandard.

Sistem pemerolehan data menghantar isyarat sensor ke platform awan dan membina model ramalan kerosakan melalui algoritma pembelajaran mesin untuk meramalkan kemungkinan kerosakan 3 hingga 5 hari lebih awal dan menjana cadangan penyelenggaraan. Selepas perusahaan acuan automotif tertentu menggunakan teknologi ini, masa henti akibat kegagalan acuan dikurangkan sebanyak 60%, dan kos penyelenggaraan diturunkan sebanyak 35%.

iv. Trend Pembangunan Masa Depan dan Cabaran Industri Acuan Suntikan

1. Integrasi mendalam kecerdasan dan automasi

Pada masa hadapan, acuan suntikan akan berkembang ke arah kecerdasan proses penuh: kecerdasan buatan (AI) akan digunakan dalam peringkat reka bentuk untuk menjana penyelesaian acuan secara automatik; Semasa peringkat pemprosesan, penjadualan pintar dan pemprosesan penyesuaian peralatan, alat pemotong dan lekapan dicapai. Semasa peringkat pengeluaran, Internet of Things (iot) digunakan untuk membolehkan kerja kerjasama acuan, mesin pengacuan suntikan dan robot, dengan itu membina barisan pengeluaran pintar tanpa pemandu.

2. Penyesuaian bahan baharu kepada proses pembentukan baharu

Dengan penggunaan meluas plastik berasaskan bio, bahan komposit berprestasi tinggi dan bahan berfungsi, acuan perlu menyesuaikan diri dengan sifat khas bahan: memandangkan penyerapan air yang tinggi bagi plastik berasaskan bio, acuan anti-karat perlu dibangunkan; Sebagai tindak balas kepada kadar pengisian bahan komposit yang tinggi, rintangan haus acuan dipertingkatkan. Untuk memenuhi keperluan pembentukan ketepatan bahan berfungsi, capai kawalan ketepatan tahap mikron.

3. Keseimbangan antara globalisasi dan penyesuaian peribadi

Di bawah latar belakang pembahagian buruh global, perusahaan acuan perlu mewujudkan rangkaian reka bentuk dan pembuatan kolaboratif merentas wilayah, dan mencapai perkongsian data reka bentuk dan penyahpepijatan jauh melalui platform awan. Pada masa yang sama, dalam menghadapi pertumbuhan permintaan peribadi pengguna, acuan perlu mempunyai keupayaan untuk bertindak balas dengan cepat dan mencapai pengeluaran tersuai kelompok kecil melalui reka bentuk modular dan parametrik.

Maklumat Berkaitan

Memasuki dunia acuan suntikan: analisis teknologi dan pembangunan perindustrian dari pelbagai perspektif

2025-06-28

Sampah boleh acuan pengeluar di China (jfmoulds.com)intotheWorldofInjectionMold...

Getah elastik acuan dan mekanisme perpisahan jarak jauh

2025-10-05

Getah anjal acuan dan mekanisme pemisahan jarak jauh: elas ...

Penyelesaian untuk mengikat dawai, lekukan permukaan dan tanda pukulan dalam acuan

2025-08-14

Penyelesaian untuk mengikat dawai, lekukan permukaan dan tanda pukulan di acuan ...

Toleransi dimensi suntikan suntikan sesuai dan kekasaran permukaan bahagian acuan

2025-09-12

Toleransi dimensi suntikan suntikan sesuai dan kekasaran permukaan mol ...

Penyelesaian untuk tanda udara di kedudukan anak panah di arah acuan, garis bayangan hitam (garis gabungan) di permukaan, dan udara yang terperangkap dan bintik putih di kedudukan lubang lampu

2025-08-13

Penyelesaian untuk tanda udara di kedudukan anak panah di arah acuan, ...

Bahagian plastik

2025-09-15

Bahagian plastik: Ketepatan dimensi plastik Partsthe ketepatan dimensi ...