Hadkan pin dan mata air acuan

Hadkan pin dan mata air acuan

Satu: Had Pin

Fungsi kuku had adalah untuk membuat jurang tertentu di antara plat rod push dan plat bawah acuan bergerak, mencegah ubah bentuk templat atau sambungan antara plat rod dan acuan bergerak

Sampah jatuh di antara plat bawah acuan, menyebabkan plat rod push gagal menetapkan semula dengan tepat. Had kuku, yang biasanya dikenali sebagai kuku sampah, biasanya diperbuat daripada bahan P-20.

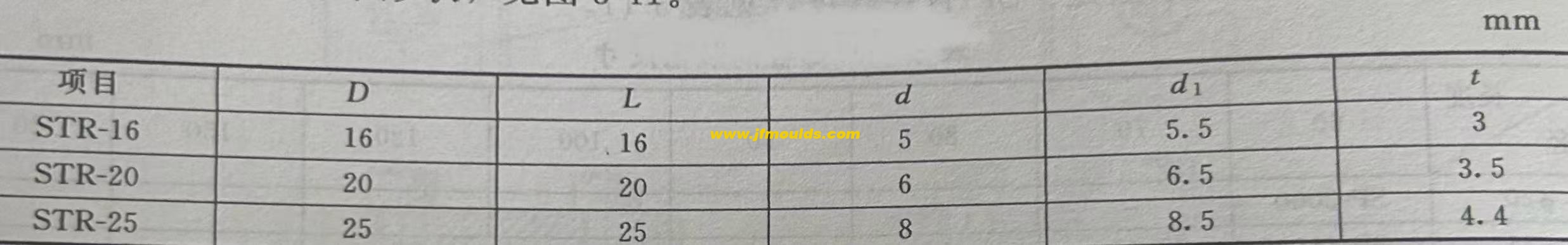

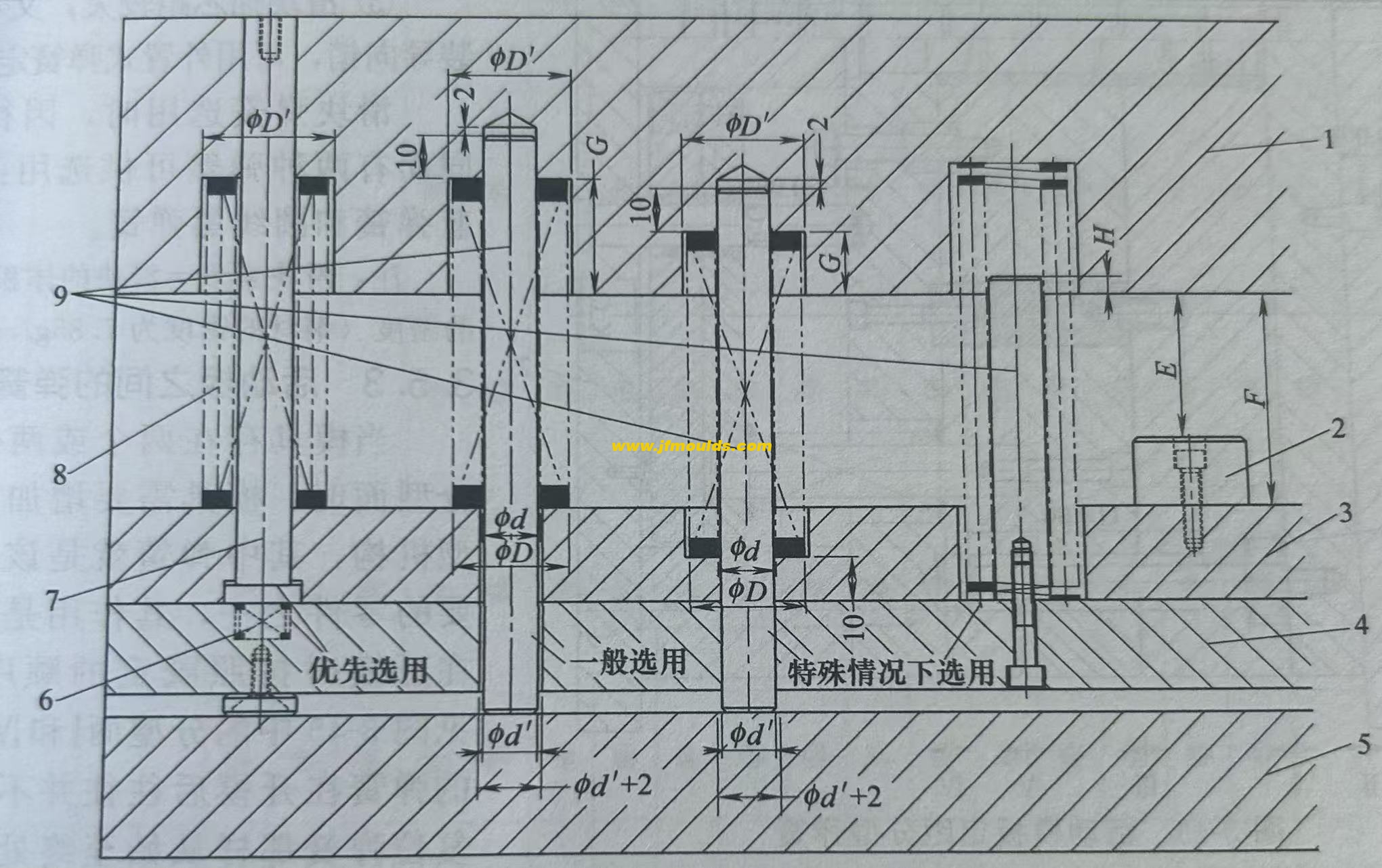

(1) Spesifikasi dan model PIN had

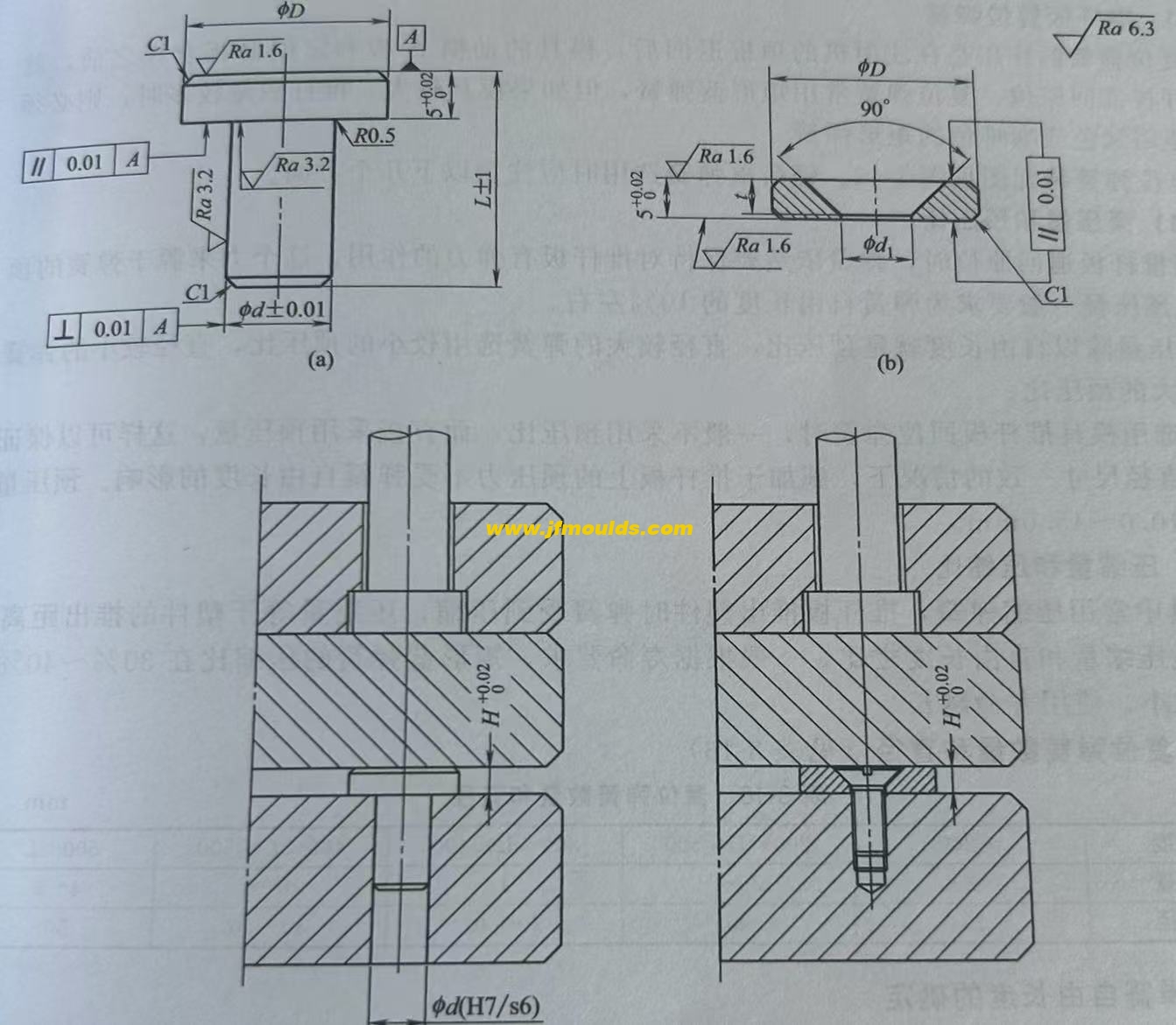

Terdapat dua bentuk standard pin had.

Pengilang acuan lampu kereta di China (jfmoulds.com)

(2) saiz pin had

(3) pemasangan kuku had

Pin had harus dipasang pada plat asas acuan bergerak. Untuk pin had integral, sesuai gangguan harus diterima pakai.

② Kedudukan pin had. Had kuku hendaklah ditambah di bawah semua rod tetapan semula, di kawasan padat batang push dan di bawah batang push cenderung untuk menahan daya pengembangan semasa suntikan acuan.

Dua: Spring

Dalam acuan, mata air terutamanya digunakan sebagai kuasa tambahan untuk komponen bergerak seperti semula plat rod push, kedudukan gelangsar dalam mekanisme penarik teras sisi, dan jarak dan pemisahan template bergerak. Oleh kerana mata air tidak mempunyai tujahan tegar dan terdedah kepada kegagalan keletihan, mereka tidak dibenarkan digunakan sendiri

Gunakan. Mata air dalam acuan termasuk mata air biru segi empat tepat dan mata air hitam bulat. Kerana mata air biru segi empat tepat mempunyai pekali elastik yang lebih besar, ketegaran yang lebih kuat dan nisbah mampatan yang lebih besar daripada mata air hitam bulat, mata air biru segi empat tepat biasanya digunakan dalam acuan.

(1) Push Rod Plate Reset Spring

Tolak plat tolak kembali ke kedudukan asalnya. Reset spring yang biasa digunakan adalah spring biru segi empat tepat, tetapi jika acuannya besar dan terdapat banyak batang tolak, mesti ada

Pertimbangkan menggunakan mata air segi empat berwarna hijau atau kopi. Apabila memilih lakaran kecil ringan, aspek berikut harus diperhatikan.

1. Jumlah preloading dan nisbah preloading

Apabila plat rod push kembali ke kedudukan asalnya, musim bunga masih perlu mengekalkan daya elastik pada plat rod push. Daya ini berasal dari tekanan teratas musim bunga, dan pra-tekanan pada umumnya diperlukan kira-kira 10% daripada panjang bebas musim bunga.

Jumlah preload yang dibahagikan dengan panjang bebas memberikan nisbah preload. Untuk mata air dengan diameter yang lebih besar, nisbah preload yang lebih kecil harus dipilih.

Apabila memilih musim bunga kembali untuk plat rod push acuan, nisbah preload biasanya tidak digunakan, tetapi jumlah preload secara langsung diterima pakai. Ini dapat memastikan bahawa, di bawah keadaan dimensi diameter musim bunga yang konsisten, preload yang digunakan untuk plat rod push tidak terjejas oleh panjang bebas musim bunga. Preload biasanya diambil sebagai 10.0 hingga 15.0mm.

2. Jumlah mampatan dan nisbah mampatan

Mata air mampatan biasanya digunakan dalam acuan. Apabila plat rod push menolak bahagian plastik, musim bunga dimampatkan, dan jumlah mampatan adalah sama dengan jarak bahagian plastik ditolak. Nisbah mampatan adalah nisbah jumlah mampatan hingga panjang bebas. Umumnya, mengikut keperluan hayat perkhidmatan, nisbah mampatan mata air segi empat tepat antara 30% dan 40%. Nisbah mampatan yang lebih kecil, semakin lama hayat perkhidmatan.

3. Bilangan dan diameter semula mata air

4. Penentuan Panjang Percuma Musim Bunga

① Free length calculation: The free length of the spring should be determined based on the compression ratio and the required compression amount. In the formula L free =(E P)/S

E is the stroke of the push rod plate, E= the minimum distance the plastic part is pushed out 15 to 20mm.

P represents the preload amount, which is generally taken as 10 to 15mm. It is determined based on the resistance during reset. The smaller the resistance, the smaller the preload. Usually, it can also be selected according to the size of the mold frame. For mold frames 3030(inclusive) or less, the preload amount is 5mm; for mold frames 3030 or more, the compression amount is 10 to 15mm.

S represents the compression ratio, typically taken as 30% to 40%. The free length should be determined based on factors such as mold life, mold size, and the distance between plastic parts. The standard length should be taken upwards.

If the calculated length is greater than the minimum length Lmin, the calculated length shall prevail.

The free length must be in accordance with the standard length and must not be cut for use. It is preferred to use multiples of 10

5. Assembly of the reset spring

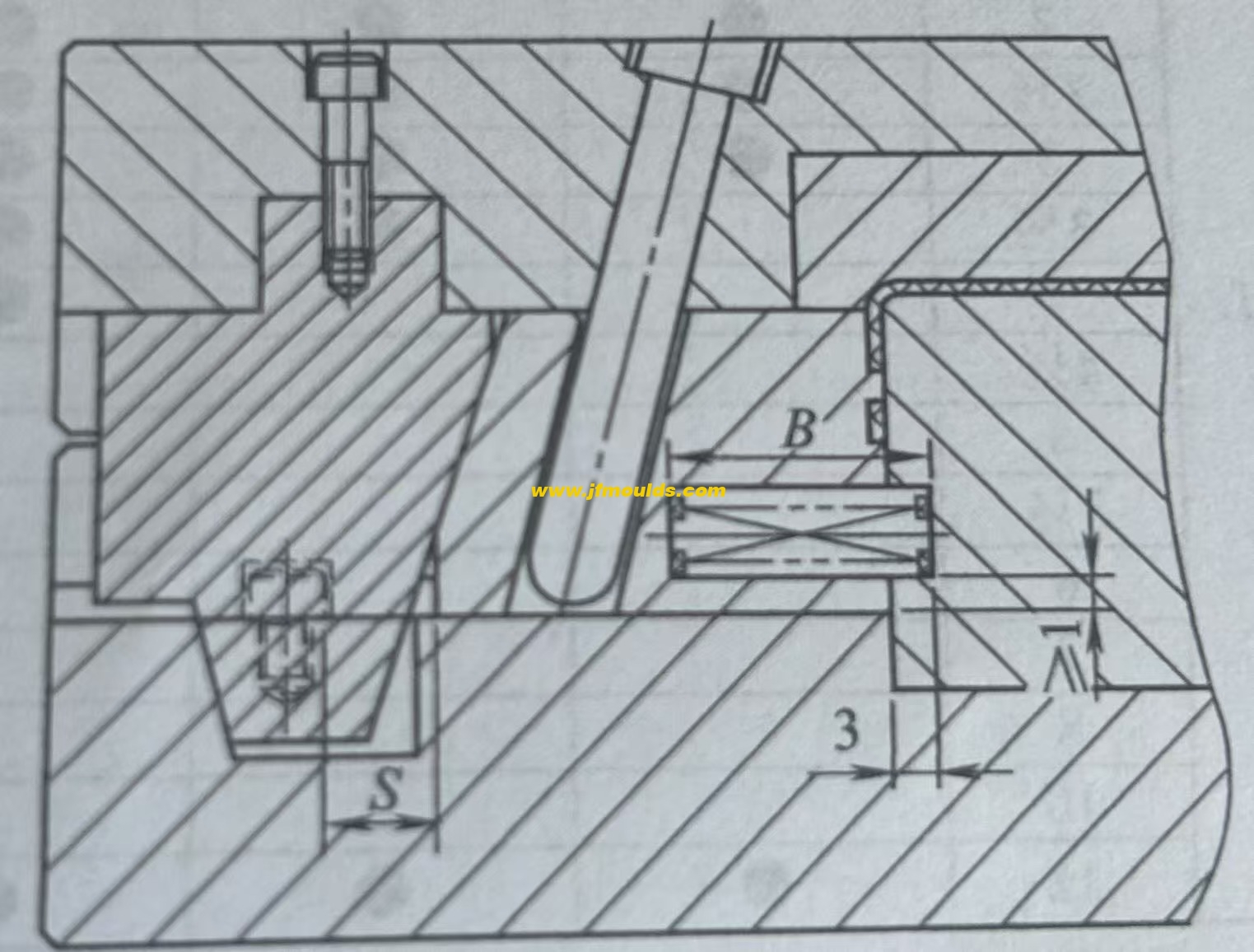

(2) Design of the slider positioning spring in the lateral core-pulling

The spring in the lateral core-pulling mechanism mainly serves a positioning function. After the mold is opened, when the inclined guide column and the wedge block leave the slider, the spring holds against the slider and does not slide back. The commonly used diameters of springs are 10mm, 20mm and 25mm. The pressure ratio can be 12mm or 16mm, and the compression ratio can be 1/4 to 1/3. The quantity is usually two.

Calculation of the free length of the slider spring: L free two-slider stroke S×3, where S is the core-pulling distance of the slider. Freedom is the free length of the spring, and the standard length should be taken upwards.

B = Free length - preload - core-pulling distance

The preload amount can be determined through calculation: slider preload amount - pressure/elastic coefficient. The upward core-pulling pressure is the slider plus the weight of the side core-pulling. When pulling the core-pulling downward or left and right, the preload can be taken as 10% of the free length.

The preloading amount can also be based on the following empirical data

Under normal circumstances, the preload after bouncing is 5mm.

If the slider is for upward core-pulling and its mass exceeds 8 to 20kg, the preload should be increased to 10mm. Meanwhile, the total length of the spring is multiplied by the stroke of the slider, S×3.5, and then rounded up to the nearest whole number.

If the slider is for upward core-pulling and its mass exceeds 20kg, the preload should be increased to 15mm.

The spring in the slider should be prevented from popping out. Therefore, the spring assembly hole should not be too large.

When the core-pulling distance of the slider is relatively large, a guide pin should be installed.

The core-pulling distance of the slider is relatively large and it is not convenient to install guide pins. An external spring can be used for positioning. When choosing a slider spring, there are two types of springs available for selection based on different strokes: rectangular blue springs and circular black springs.

Note: The weight of the slider × the volume of the slider × the steel material

The density (the density of steel is 7.85g/cm ³)

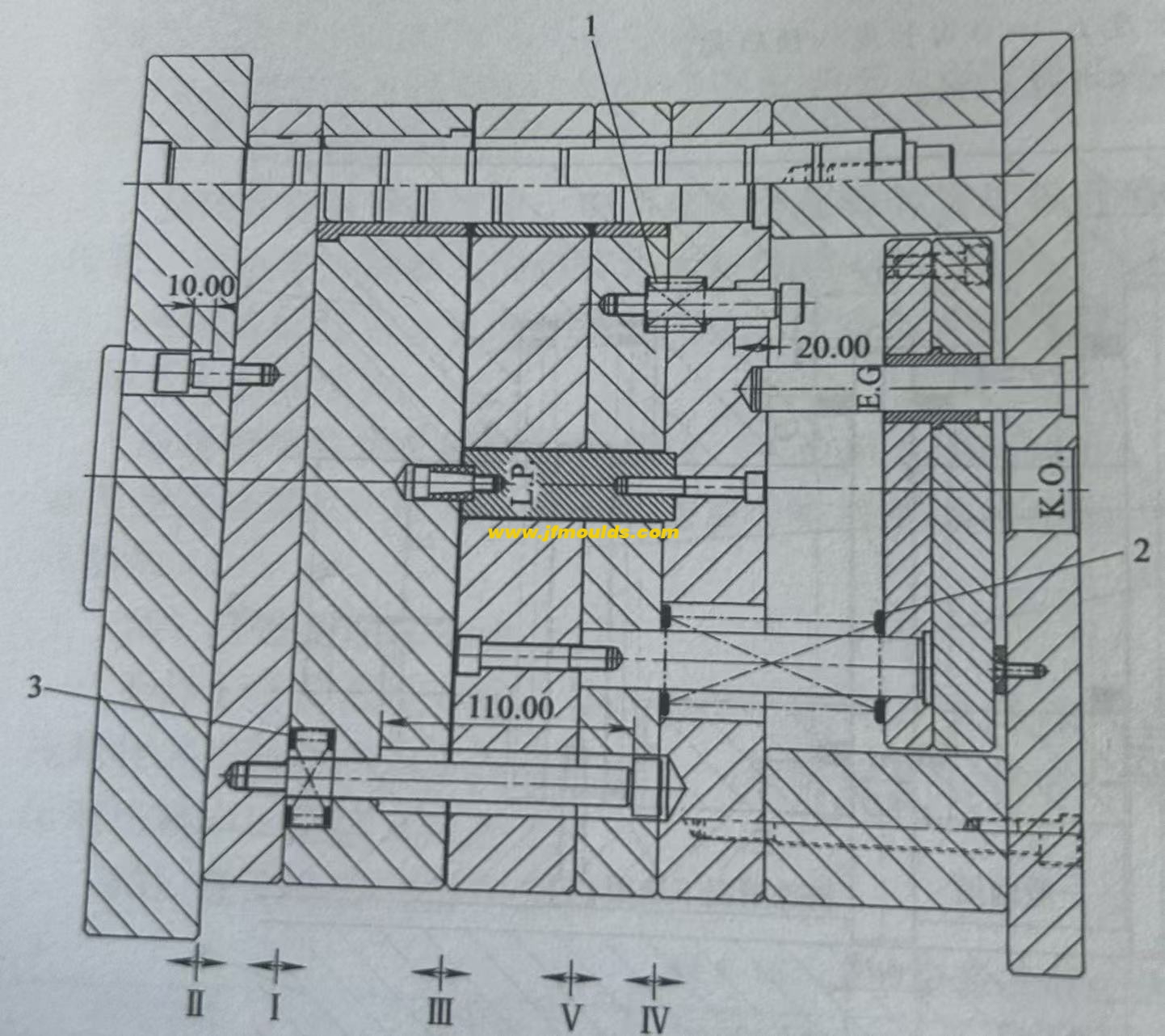

(3) Springs between the movable plates

When a mold has two or more parting surfaces, a space-fixing parting mechanism needs to be added to the mold. Among them, the spring is one of the important parts of this mechanism. Its function is to enable the mold to open in the predetermined sequence during mold opening, with parting surfaces I and V. Here, the spring usually does not need to be in a compressed state from beginning to end like the reset spring after mold opening. The spring only needs to be pressed on this parting surface

For the first 10 to 20mm of opening, just maintain the thrust on the template. As long as this surface is opened on time, its task is completed. For the three-plate mold that usually adopts the point gate gating system, the springs used on the first parting surface are all rectangular yellow springs of $40mmX30mm. The opening springs for other molds can be selected according to specific circumstances.

Maklumat Berkaitan

Penyelesaian untuk tanda udara di kedudukan saluran air acuan dan seret kerosakan di kedudukan keluar air bingkai bateri

2025-08-27

Penyelesaian untuk tanda udara di kedudukan saluran air acuan dan kerosakan seret ...

Cara menyelesaikan masalah pemutihan, penyamaran dan ubah bentuk kedudukan tulang di saluran air acuan

2025-08-16

Cara Menyelesaikan Masalah Pemutihan, Menggoda dan Deformasi Bone Pos ...

Penyelesaian kepada masalah dimensi panjang lensa acuan terlalu besar dan garis air diapit di sisi kedudukan lubang tengah

2025-08-11

Penyelesaian kepada masalah dimensi panjang lensa acuan terlalu ...

Wawasan panorama ke dalam industri acuan suntikan: maju ke hadapan dalam gelombang perubahan

2025-07-04

Wawasan panorama ke dalam industri acuan suntikan: maju ke hadapan dalam gelombang...

Bagaimanakah kerosakan air masuk air acuan yang kerap, kedudukan tulang yang dibangkitkan dan gam yang berlebihan di sisi (kilat) diselesaikan

2025-08-22

Bagaimanakah pemecahan jarum salur masuk air yang kerap, yang dibangkitkan ...

Analisis mendalam industri acuan suntikan: keadaan semasa, cabaran dan peluang

2025-07-05

Analisis dalam kedalaman industri acuan suntikan: keadaan semasa, cabaran...