Cara menyelesaikan masalah penyok permukaan dan acuan pada acuan suntikan

Cara menyelesaikan masalah penyok permukaan dan acuan pada acuan suntikan

Titik cekung di permukaan acuan suntikan

Fenomena: Titik cekung di permukaan bingkai muka

Sebab: Semasa pencetakan suntikan dalam bahan-bahan lembaran IML, banyak titik cekung muncul di permukaan produk.

Analisis: Terdapat sedikit habuk di permukaan lembaran PC. Kebersihan udara di alam sekitar tidak tinggi, dan terdapat banyak habuk, yang menyebabkan kemurungan berlaku apabila lembaran diletakkan di dalam acuan untuk pengacuan suntikan.

(1) Ciri -ciri mesin pengacuan suntikan

Gred: Demag, Pasukan Pengapit: 50T, Kapasiti Plastik: 42g.

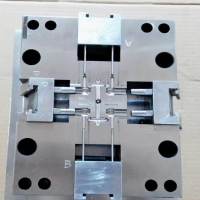

(2) Ciri -ciri acuan

Nombor Letupan Acuan: 1 × 2, Kaedah Suntikan Gam: Pintu Pintu, Kaedah Letakkan: Letakkan oleh Pin Ejector, Suhu Acuan: 70 ° C (mesin suhu malar)

(3) Bukti Fizikal Produk

Bahan: ABS PA758, Warna: telus, berat produk (sekeping tunggal): 2.4g, berat sprue: 8.44g.

(4) Analisis penyebab kecacatan

1. Terdapat sedikit habuk di permukaan lembaran PC. Apabila ia diletakkan di dalam acuan untuk pengacuan suntikan, bintik -bintik debu disuntik ke permukaan produk.

2. Persekitaran udara bersih dengan banyak habuk. Apabila acuan dibuka, debu mematuhi permukaan teras acuan depan dan menyebabkan titik cekung apabila acuan seterusnya dikitar semula.

(5) Penangguhan

1. Secara manual mengelap permukaan bahan lembaran untuk meminimumkan titik debu.

2. Memurnikan kesucian udara dan kerap membersihkan mesin dan persekitaran sekitarnya.

Jadual proses pencetakan suntikan

Mesin Pencetakan Suntikan: Demag50t, Jenis B Skru, Kapasiti Suntikan 42g | Nama Produk: bingkai muka S10 | ||||

Bahan Mentah: Abs PA785 | Warna: telus | Suhu pengeringan: 80 ° C. | Kaedah pengeringan: pengering dehumidifikasi | Masa pengeringan: 2 jam | Penggunaan Bahan Kitar Semula: 0 |

Berat produk siap: 2.4g × 2 = 4.8g | Berat Nozzle: 8.44g | Output acuan: 1 × 2 | Kaedah Suntikan Pintu: Pintu Pintu | ||

Suhu barel | Suhu acuan | Gunakan mesin | "Tetapan | "Sebenarnya | ||||

| 1 | 2 | 3 | 4 | 5 | sebelumnya | Mesin suhu air | 70°C | 62°C |

| 260°C | 255°C | 250°C | 220°C | / | ||||

| △ | △ | △ | △ | △ | after | Mesin suhu air | 70°C | 59°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 | Injection pressure | ||

| / | 3 | Holding pressure time | 12 | 12 | Injection position | ||||

Residual amount of injection glue | 10 | / | 55 | 3 | Injection velocity | ||||

| 7.8 | / | / | 12 | 23.5 | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Kereta Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

The injection mold is moldy

Reason: This is an IML injection molded product. Due to the temperature difference on the mold surface when the sheet is installed, it forms a semi-transparent state.

Analysis: High speed will cause material melting, intensify shearing, generate high temperatures and be prone to decomposition. The surface temperature of the mold is too low. The temperature of the material pipe is too low.

(1)Characteristics of injection molding machines

Grade: DEMAG (Ningbo), clamping force: 50t, plasticizing capacity: 42g.

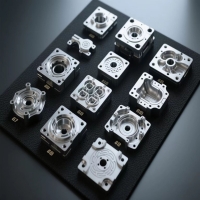

(2) Ciri -ciri acuan

Mold ejection number: 1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 60°C (constant temperature machine)

(3) Bukti Fizikal Produk

Material: ABS PA758, Color: Transparent, Product weight (single piece) : 2.43g, sprue weight 8.44g.

(4) Analisis penyebab kecacatan

The mold temperature is low, and the inlet method is potential inlet. The molten material flows to the vicinity of the inlet. Due to the excessive speed and the very smooth surface of the mold, high shear occurs, causing the molten material to heat up rapidly in an instant, until the surface turns white and forms a semi-transparent state.

(5) Countermeasures

1. Menggunakan suntikan pelbagai peringkat dan penukaran kedudukan.

2. Appropriately increase the mold temperature to allow the product to cool down slowly in the mold.

3. Appropriately increase the temperature of the melt cylinder to enhance the transparency of the product.

Jadual proses pencetakan suntikan

| Injection molding machine: Demag 50T, Type B screw, injection capacity 42g | Product Name: S10 Face Frame | ||||

| Raw material: ABS PA758 | Warna: telus | Suhu pengeringan: 80 ° C. | Kaedah pengeringan: pengering dehumidifikasi | Masa pengeringan: 2 jam | Penggunaan Bahan Kitar Semula: 0 |

Finished product weight: 2.43g×2=4.86g | Berat Nozzle: 8.44g | Output acuan: 1 × 2 | Kaedah Suntikan Pintu: Pintu Pintu | ||

Suhu barel | Suhu acuan | Gunakan mesin | "Tetapan | "Sebenarnya | ||||

| 1 | 2 | 3 | 4 | 5 | sebelumnya | Oil temperature control machine | 80°C | 73°C |

| 242°C | 236°C | 227°C | 200°C | / | ||||

| △ | △ | △ | △ | △ | after | Oil temperature control machine | 80°C | 67°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 | Injection pressure | ||

| / | 3 | Holding pressure time | 12 | 12 | Injection position | ||||

Residual amount of injection glue | / | 10 | / | 55 | 3 | Injection velocity | |||

| 7.8 | / | / | / | 12 | 23.5 | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Komoditi Mould_Taizhou Jiefeng acuan co, Ltd. (jfmoulds.com)

Maklumat Berkaitan

Penetapan tekanan pencetakan dan parameter aliran suntikan

2025-07-26

Penetapan tekanan pencetakan suntikan dan parameter aliran1.Setting suntikan ...

Kecacatan biasa produk acuan suntikan dan penyelesaiannya

2025-07-29

Kecacatan biasa produk acuan suntikan dan penyelesaian mereka diagnosis ...

Penyelesaian untuk penyingkiran, mengelupas, pengerasan dan kerapuhan produk yang dibentuk suntikan

2025-08-01

Penyelesaian untuk penyingkiran, mengelupas, pengerasan dan kerapuhan suntikan yang dibentuk ...

Kepelbagaian perusahaan acuan suntikan

2025-06-28

Kepelbagaian acuan suntikan enterprises1. Acuan automotif: memandu...

Acuan pelbagai komponen

2025-07-25

Multi-komponen Moldin Multi-Component Suntikan Molding (juga dikenali sebagai Multi-Co ...

Kunci pencetakan produk plastik

2025-07-21

Kunci Produk Plastik Moldingbehind Dunia Produ Plastik yang mempesonakan hari ini ...